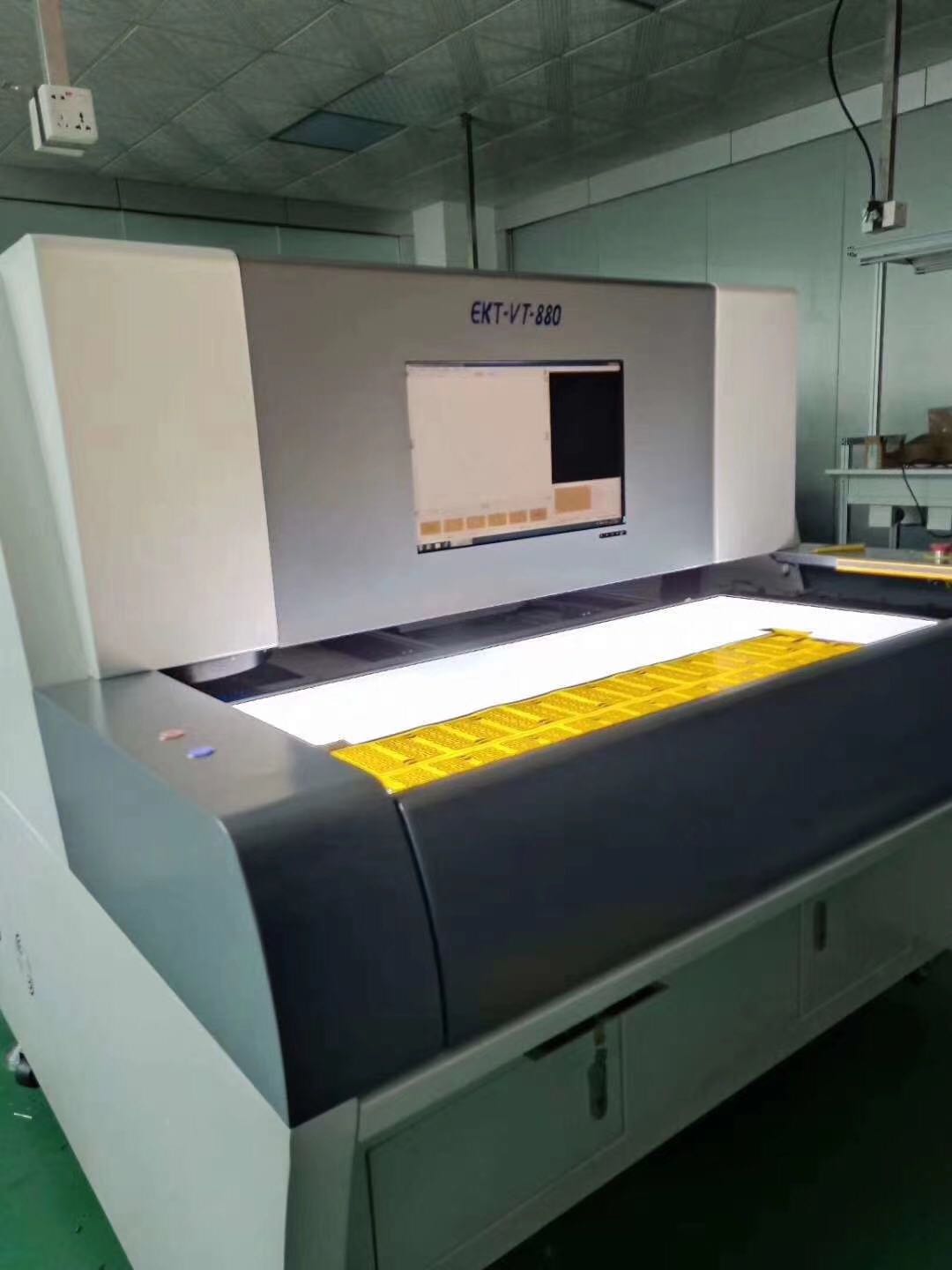

Wholesale SMT Optical Inspection - Bottom-camera online AOI EKT-VL-800B – Ektion

Wholesale SMT Optical Inspection - Bottom-camera online AOI EKT-VL-800B – Ektion Detail:

Bottom Camera Online AOI: EKT-VL-800B

Product features:

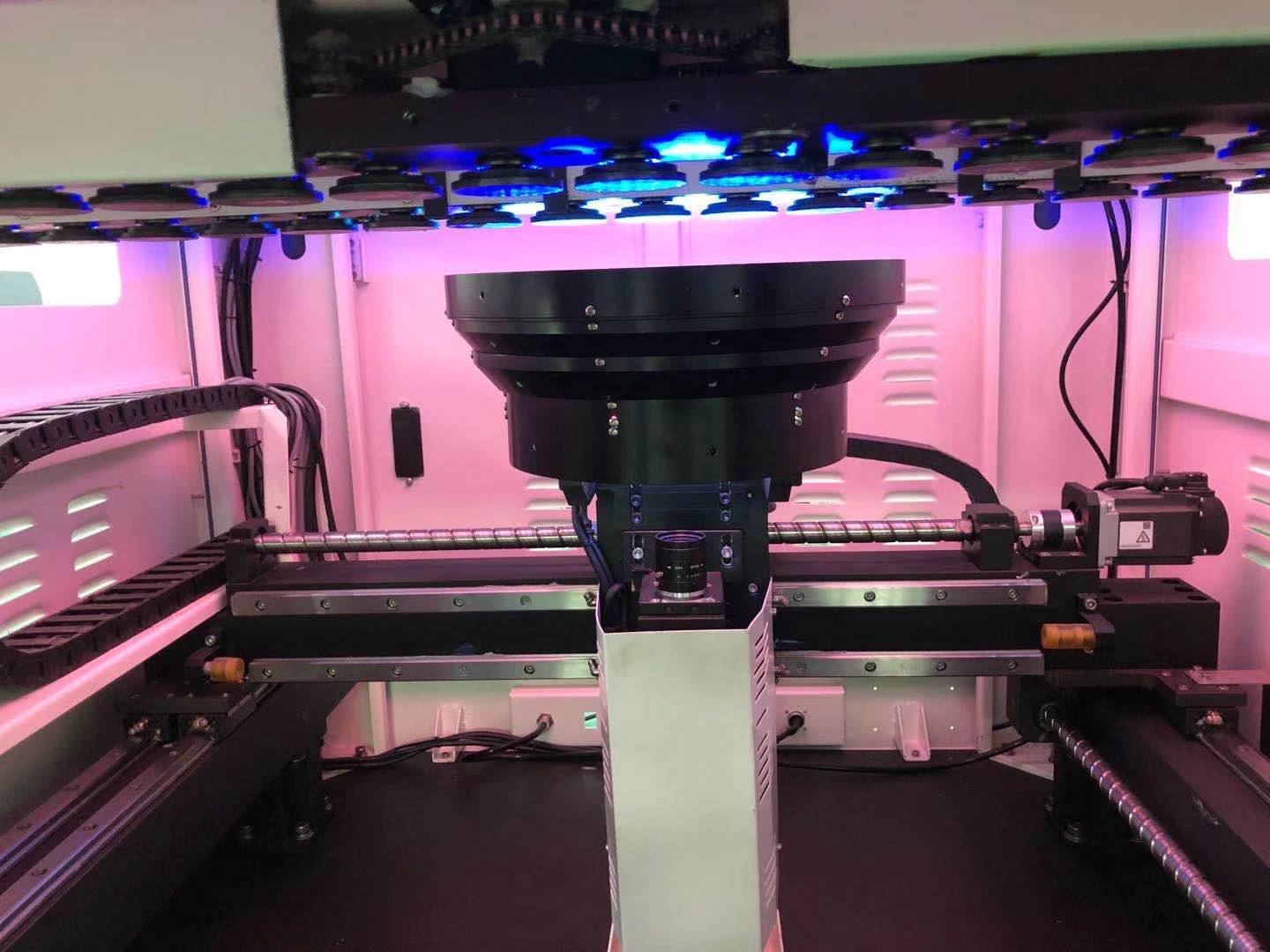

l XY platform moving under PCB conveyor, camera and light source coordinated and taking images from bottom up.

l Applicable to soldering surface after wave soldering.

l 5 million pix full-color high speed digital camera (20 million pix optional), ensure high efficiency, high quality and high stability of image shooting, restore the real and natural image effect.

l Lens resolution can be flexibly adjusted range from 10-25um to apply for different requirement.

l Windows 7 x64 operation system,high data processing speed.

l Thousands of sales, advanced and upgraded configuration and continuous technological innovation based on 6 series AOI products, high stability and efficiency.

l Optional telecentric lens with high resolution, unique parallel light design, PCBA tilted or tall components can be distinctly displayed.

l Intelligent and fast programming,intelligent algorithm, no need of manual intervention, easy to learn, high detection rate, low error rate.

l Flexible and mobile maintenance station and SPC checking terminal.

Mobile devices under wireless network, working station can be set up flexibly on workshop in one to many mode: the detection data of multiple online machines can be checked through one maintenance workstation, the defect details are clearly reported. SQL data system are well-defined, SPC report with pie chat and histogram, very convenient for customer process analysis and quality improvement.

l Convenient and practical offline programming software OLP. PCB genuine image can be taken in real time and stored in full memory, ensure high efficient programming under circumstances of either online or offline.

l Multi–angle ring power long-life high-brightness LED light source with excellent positioning capabilities; can be applied to a variety of circuit boards, including non-mark spots.

l High precision and reliable mechanical and electrical system, X/Y driving system applied AC servo motor and high precision grinding ball screw with reliable performance.

l PCB auto fixing, rapid and accurate positioning without manual operation, fast adjustment&visible operation.

l Can link to customer MES system

Specifications: EKT-VL-800B

|

Inspection system |

Application |

After SMT stencil printing, pre/post reflow oven, pre/post wave soldering, FPC |

|

Program mode |

Manual programming, auto programming, CAD data importing |

|

|

Inspection Items |

Stencil printing: Solder unavailability, insufficient or excessive solder, solder misalignment, bridging, stain, scratch etc. |

|

|

Component defect: missing or excessive component, misalignment, uneven, edging, opposite mounting, wrong or bad component etc. |

||

|

DIP: Missing parts, damage parts, offset, skew, inversion, etc |

||

|

Calculation Method |

Machine learning, color calculation, color extraction, gray scale operation, image contrast , OCV/OCR etc. |

|

|

Inspection mode |

Optimized inspection technology covering the whole PCBA board, support collating board inspection and multi-mark |

|

|

SPC statistics function |

Fully record the test data and make analysis,,with high flexibility to check production and quality status. |

|

|

Component angle |

Support 0~359° rotation,minimum angular distance 1° |

|

|

Minimum component |

01005 chip、0.3 pitch IC |

|

| Optical system

|

Camera |

5 million pix full color high speed industrial digital camera , 20 million pix camera optional |

|

Lens resolution |

10um/15um/18um/20um/25um, can be customized |

|

|

lighting source |

Self-configurable ring stereo multi-channel color light source, selection depending on application, RGB/RGBW/RGBR/RWBR, coaxial light source or large light source optional |

|

|

Computer system |

OS |

Windows 7 64bit |

|

Display |

22inch, 16:10 |

|

|

CPU |

Inter E3 or same level |

|

|

GPU |

optional |

|

|

RAM |

16GB |

|

|

HDD |

1TB HDD,SSD optional |

|

|

Software |

Language |

Chinese/English optional |

|

Access Control |

Administrator,programmer, operator 3 levels access control. |

|

Mechanical system |

Moving and inspection mode |

PCB automatic moving in and out, L-R/R-L direction optional, step motor drives PCB rail, XY servo motor drives camera shooting image. |

|

Width adjusting |

Automatic |

|

|

PCB fixing mode |

Auto fixture |

|

|

PCB dimension |

50*50mm(Min)~520*510, can be customized base on need |

|

|

PCB thickness |

0.3~5.0mm |

|

|

PCB weight |

Max:3KG |

|

|

PCB edge |

3mm,can be customized base on need |

|

|

PCB bending |

<5mm or 3% of PCB diagonal length |

|

|

PCB component height |

Top:50mm,Bottom:35mm。Adjustable, can be customized base on need |

|

|

XY driving system |

AC servo motor, precise ball screw |

|

|

XY moving speed |

Max:830mm/s |

|

|

XY positioning accuracy |

≦8um |

|

|

General parameters |

Machine dimension |

L1380 * W1210 * H1700 mm |

|

Power |

AC220V,50/60Hz,2 KW |

|

|

PCB height from ground |

720±20mm |

|

|

Machine weight |

650KG |

|

|

Connection with other SMT machine |

Smema |

|

|

Air pressure |

0.4 – 0.8MPa |

|

|

Safety standard |

CE safety standard |

|

|

Environment temperature and humidity |

10~35℃,35~80% RH(non condensing) |

|

|

Optional |

configuration |

Maintenance station, offline programming system, SPC servo, bar code system |

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" could be the persistent conception of our organization for your long-term to establish alongside one another with shoppers for mutual reciprocity and mutual benefit for Wholesale SMT Optical Inspection - Bottom-camera online AOI EKT-VL-800B – Ektion , The product will supply to all over the world, such as: Kuala Lumpur , Macedonia , Denmark , Our team knows well the market demands in different countries, and is capable of supplying suitable quality products at the best prices to different markets. Our company has already set up a professional, creative and responsible team to develop clients with the multi-win principle.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.