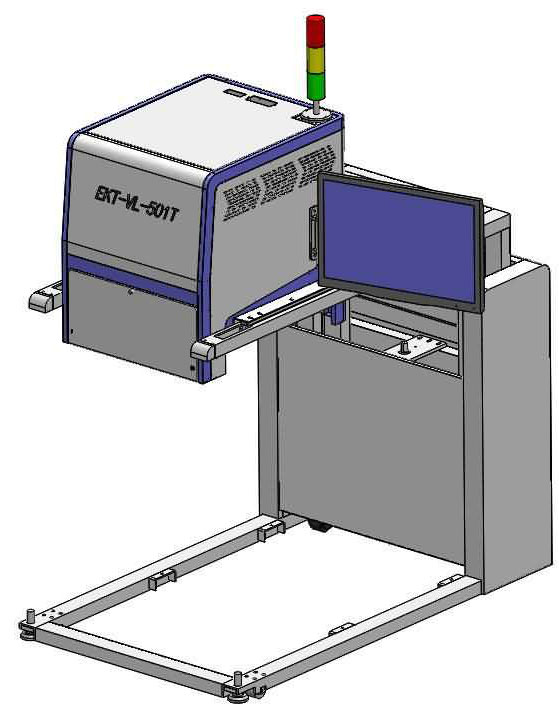

Wholesale AOI In SMT Process - Overal-view DIP online AOI EKT-VL-501T – Ektion

Wholesale AOI In SMT Process - Overal-view DIP online AOI EKT-VL-501T – Ektion Detail:

• Modular structure, easy to install and move.

• Apply to various production line flexibly, no disturb for the state of original production line.

• Common inspection items: wrong/missing/offset of components, barcode, packing inspection, etc.

• Automatically select the optimal combination effect of camera, lens and light source.

• Test result stored and summarized in SPC, with auto-alarming system.

• Compatible with functions of series 8 products.

• 12 million pix camera, 15 million pix optional, each with different lens.

Specifications EKT-VL-501T:

|

|

|

Overall-view DIP online AOI EKT-VL-501T |

|

Inspection system |

Application |

Pre/post DIP wave soldering |

|

Program mode |

Manual programming, auto programming, CAD data importing, offline programming |

|

|

Inspection Items |

DIP :Missing parts, damage parts, offset, skew, inversion, etc |

|

|

Calculation Method |

Machine learning, color calculation, color extraction, gray scale operation, image contrast |

|

|

Inspection mode |

Single lens covers whole PCBA to inspect, fast speed, support continuous detection without pause, support collating board inspection and multi-mark, support various board on same line, with function of bad mark. |

|

|

Result display |

Online support 20 boards result cache display, support database plug-in display, NG result voice broadcasting. |

|

|

SPC statistics function |

Fully record the test data and make analysis,,with high flexibility to check production and quality status. Inspected picture and data saved synchronously by serial number. |

|

| Component angle |

Support 0~359° rotation,minimum angular distance 1° |

|

| Minimum component |

1 mm |

|

| Optical system

|

Camera |

High-speed global exposure industrial digital camera 12million pix camera,support shooting in motion |

|

Lens resolution |

10um/15um/18um/20um/25um,can be customized |

|

|

lighting source |

Top and side LED lighting board |

|

|

Computer system |

CPU |

Intel i7 or same level |

|

RAM |

8GB |

|

|

SSD |

128GB |

|

|

OS |

Win7 64bit |

|

|

Monitor |

22inch ,16:10 |

|

|

Mechanical system |

Moving and inspection mode |

PCB board moving controlled by customer production line. Support rail conveyor and belt line, automatic correction for bias and angle by pcb mark positioning. |

|

PCB dimension |

50*50mm(Min)~500*500mm(Max), can be customized |

|

|

PCB thickness |

0.3~5.0mm |

|

|

PCB weight |

Max:3KG |

|

|

Production line speed |

Max : 3.5m /min |

|

|

PCB edge |

3mm,can be customized base on need |

|

|

PCB bending |

<5mm,or 3% of PCB Diagonal length |

|

|

PCB component height |

50mm,adjustable,can be customized base on need |

|

|

General parameters |

Machine dimension |

L710mm * W600mm * H700 mm,height does not include signal light |

|

Power |

AC220V,50/60Hz,1.0KW |

|

|

PCB height from ground |

Not limited,AOI directly working on production line |

|

|

Machine weight |

90KG |

|

|

Safety standard |

CE safety standard |

|

|

Environment temperature and humidity |

10~35℃,35~80% RH(non condensing)

|

|

|

|

Optional configuration |

Maintenance station, offline programming system, SPC servo, bar code system |

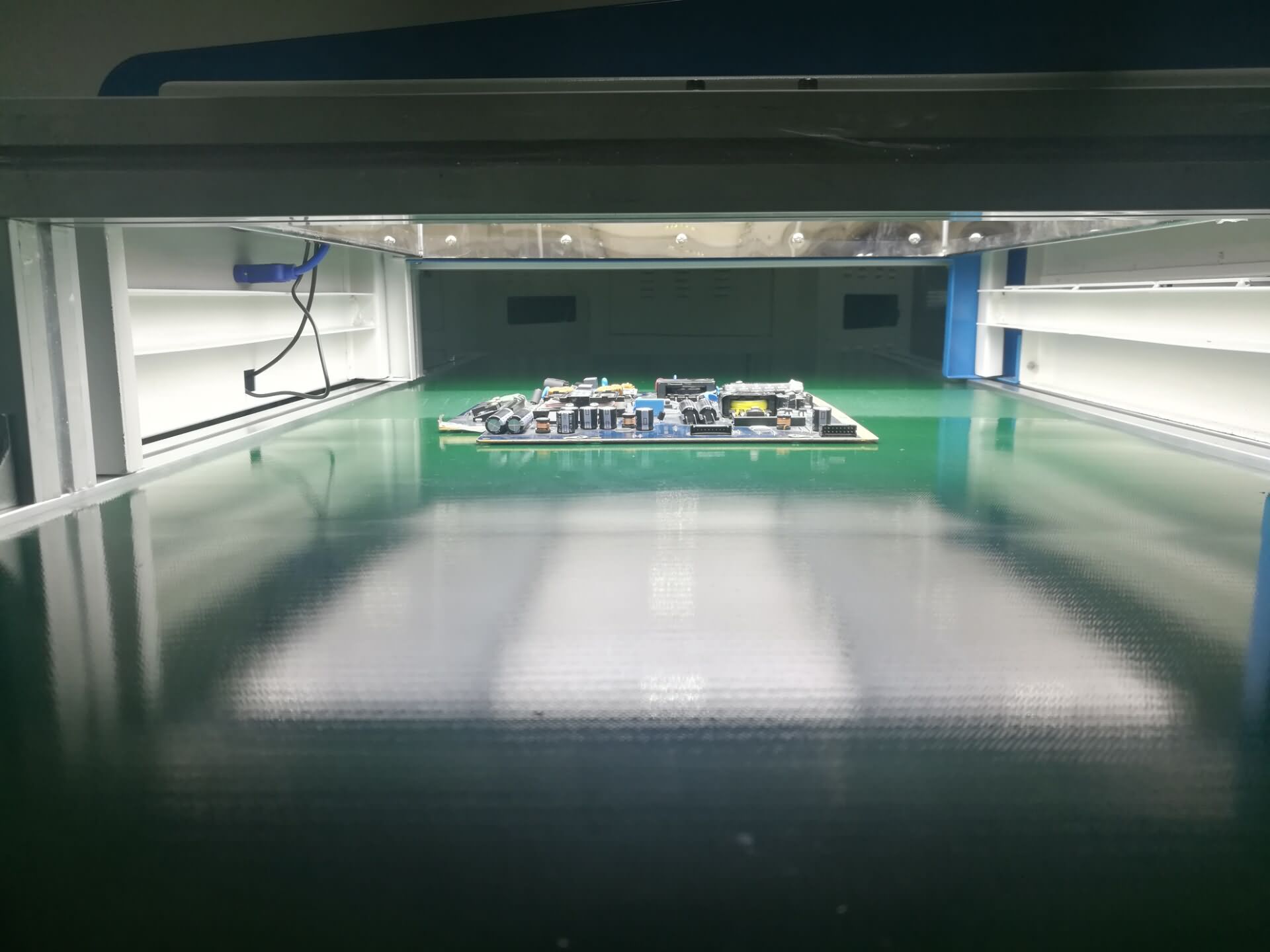

Product detail pictures:

Related Product Guide:

Being supported by an highly developed and skilled IT group, we could offer you technical support on pre-sales & after-sales support for Wholesale AOI In SMT Process - Overal-view DIP online AOI EKT-VL-501T – Ektion , The product will supply to all over the world, such as: Bandung , Azerbaijan , European , We've been adhering to the philosophy of "attracting customers with the best items and excellent service". We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.