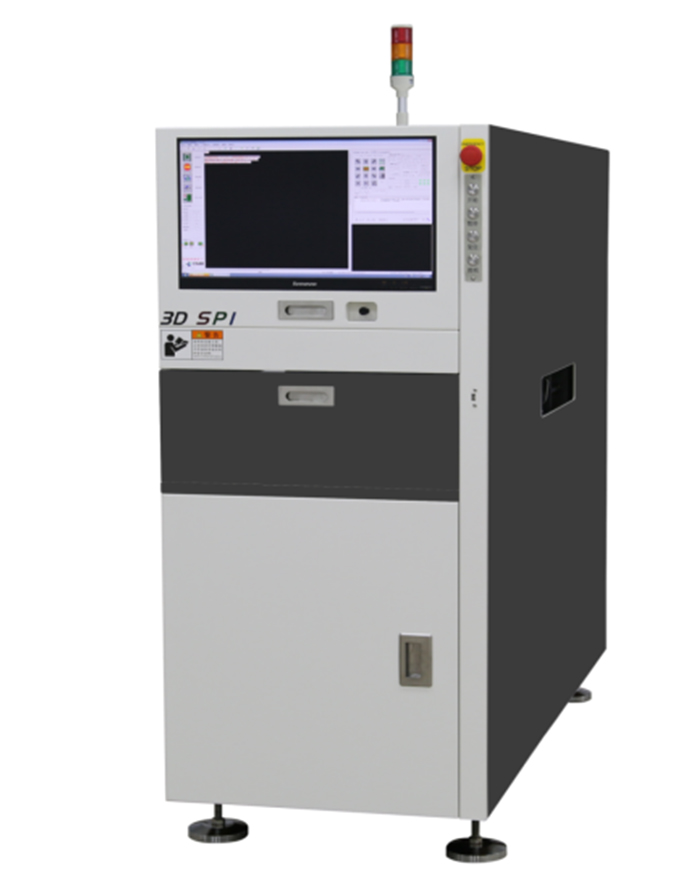

Wholesale AOI In SMT Process - Advanced plus offline AOI EKT-VT-980 – Ektion

Wholesale AOI In SMT Process - Advanced plus offline AOI EKT-VT-980 – Ektion Detail:

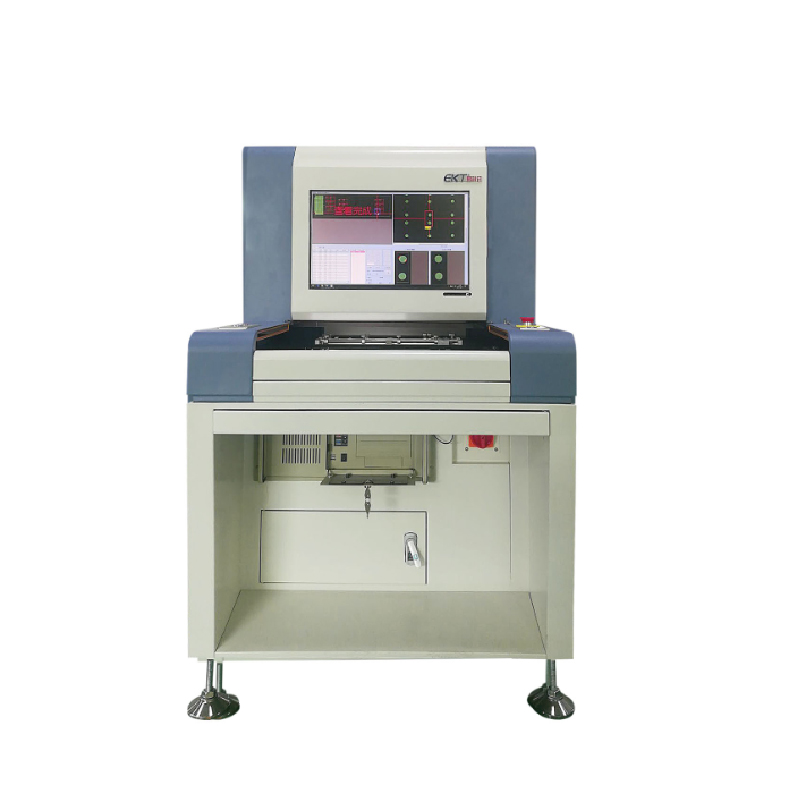

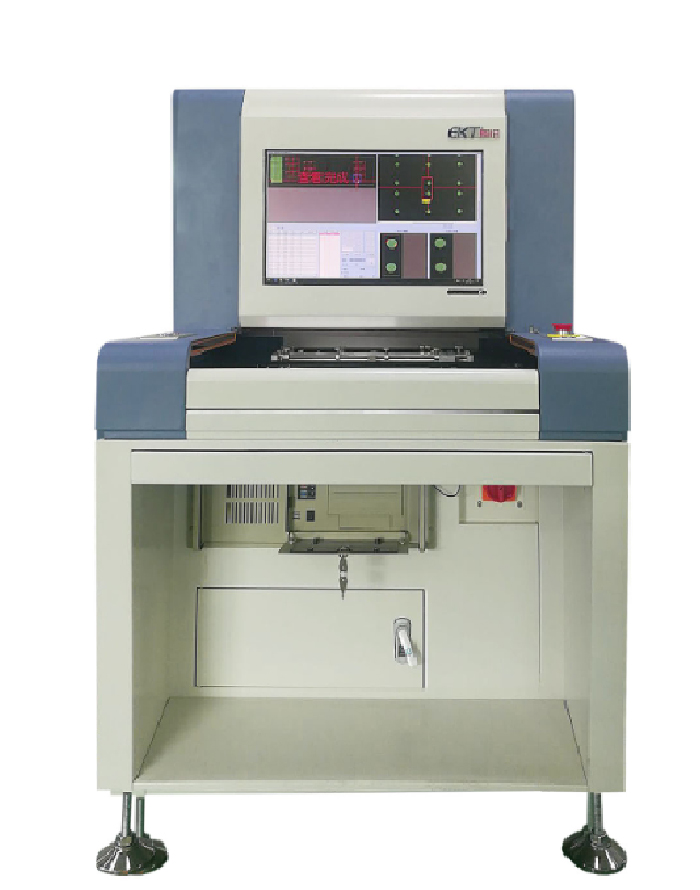

l Whole new appearance,more friendly design

l Customized high brightness wide view annular light source, light source, maximum FOV effective coverage area: 50*50mm, camera moving reduced and detect time shortened.

l Win10 64 bit OS,more stable

l CPU upgraded to i7 series,inspection speed faster

l Added vector analysis method, a series of improvements made to traditional algorithms such as color extraction.

Specifications: EKT-VT-980

| Inspection system | Application | After stencil printing, pre/post reflow oven, pre/post wave soldering, FPC etc. |

| Program mode | Manual programming, auto programming, CAD data importing | |

| Inspection Items | Stencil printing: Solder unavailability, insufficient or excessive solder, solder misalignment, bridging, stain, scratch etc. | |

| Component defect: missing or excessive component, misalignment, uneven, edging, opposite mounting, wrong or bad component etc. | ||

| Soldering defect: excessive or missing solder, empty soldering, bridging, solder ball, IC NG ,copper stain etc. | ||

| Calculation Method | Template matching, color calculation, vector analysis, color extraction, gray scale operation, characteristics analysis, OCV/OCR etc | |

| Inspection mode | PCB fully covered, with array and bad marking function | |

| SPC statistics function | Fully record the test data and make analysis, with high flexibility to check production and quality status | |

| Components angle | Angle 0~359°flexible,min angular distance 1° | |

| Min components | 01005 chip、0.3 pitch IC | |

| Optical system | Camera | 5 million pix full color high speed industrial digital camera , 20 million pix camera optional |

| Lens resolution | 10um/15um/18um/20um/25um, can be custom-made | |

| lighting source | Annular stereo multi-channel color light, RGB/RGBW/RGBR/RWBR optional, maximum FOV effective coverage area: 50*50mm | |

| Computer system | OS | Win 10, 64bit |

| Monitor | 22寸,16:10 | |

| CPU | Intel i7 series | |

| GPU | optional | |

| RAM | 16GB, may increase to 32GB | |

| HDD | 1TB , (SSD optional) | |

| Software | Language | Chinese, English optional |

| Access control | Admin/programmer/operator 3-level access control | |

| Mechanical system | Moving and inspection mode | Manual taking board in and out, Y servo motor driving PCB, X servo motor driving camera |

| Fixture | Auto fixture | |

| PCB dimension | 20*20mm(Min)~450*350mm(Max), can be customized | |

| PCB thickness | 0.3~5.0mm | |

| PCB weight | Max:3KG | |

| PCB edge | 3mm,can be customized | |

| PCB bending | <5mm or 3% of PCB Diagonal length | |

| PCB component height | Top:35mm,Bottom:75mm Adjustable, can be customized base on need | |

| XY driving system | AC servo motor, precise ball screw | |

| XY moving speed | Max:830mm/s | |

| XY positioning accuracy | ≦8um | |

| General parameters | Machine dimension | L1140 * W890 * H1500 mm |

| Power | AC220V,50/60Hz,1.5KW | |

| PCB height from ground | 820±20mm | |

| Machine weight | 450KG | |

| Safety standard | CE safety standard | |

| Environment temperature and humidity | 10~35℃,35~80% RH | |

| (non condensing) | ||

| Optional | configuration | Maintenance station, offline programming system, SPC servo, bar code system |

Product detail pictures:

Related Product Guide:

It adheres for the tenet "Honest, industrious, enterprising, innovative" to develop new products and solutions continuously. It regards shoppers, success as its individual success. Let us produce prosperous future hand in hand for Wholesale AOI In SMT Process - Advanced plus offline AOI EKT-VT-980 – Ektion , The product will supply to all over the world, such as: Madras , Angola , United States , With many years good service and development, we've a professional international trade sales team. Our products have exported to North America, Europe, Japan, Korea, Australia, New Zealand, Russia and other countries. Looking forward to build up a good and long term cooperation with you in coming future!

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.

Write your message here and send it to us