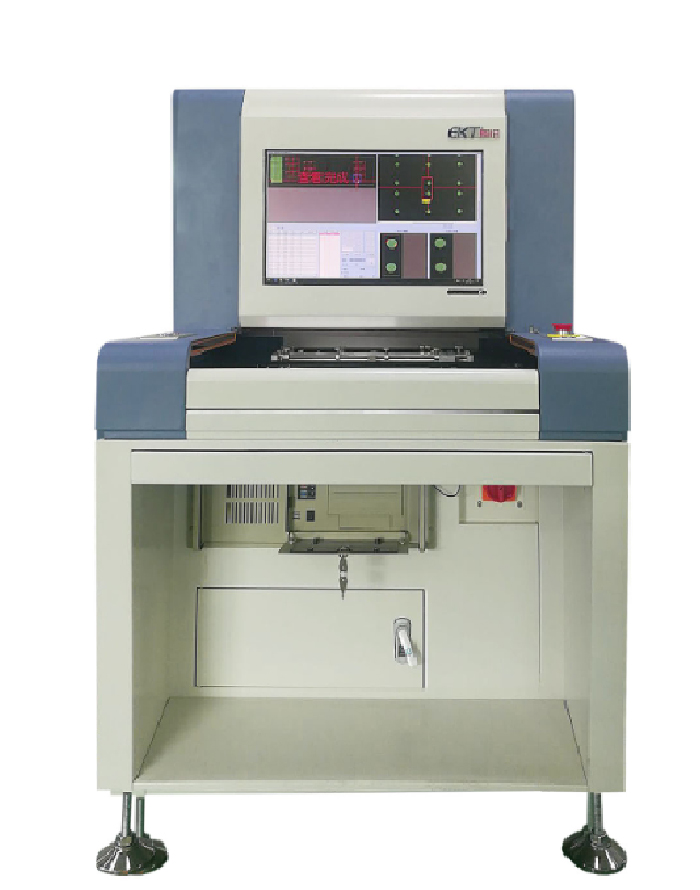

Quality Inspection for China Pcb Aoi Systems - Offline AOI EKT-VT-680 – Ektion

Quality Inspection for China Pcb Aoi Systems - Offline AOI EKT-VT-680 – Ektion Detail:

Product Detail:

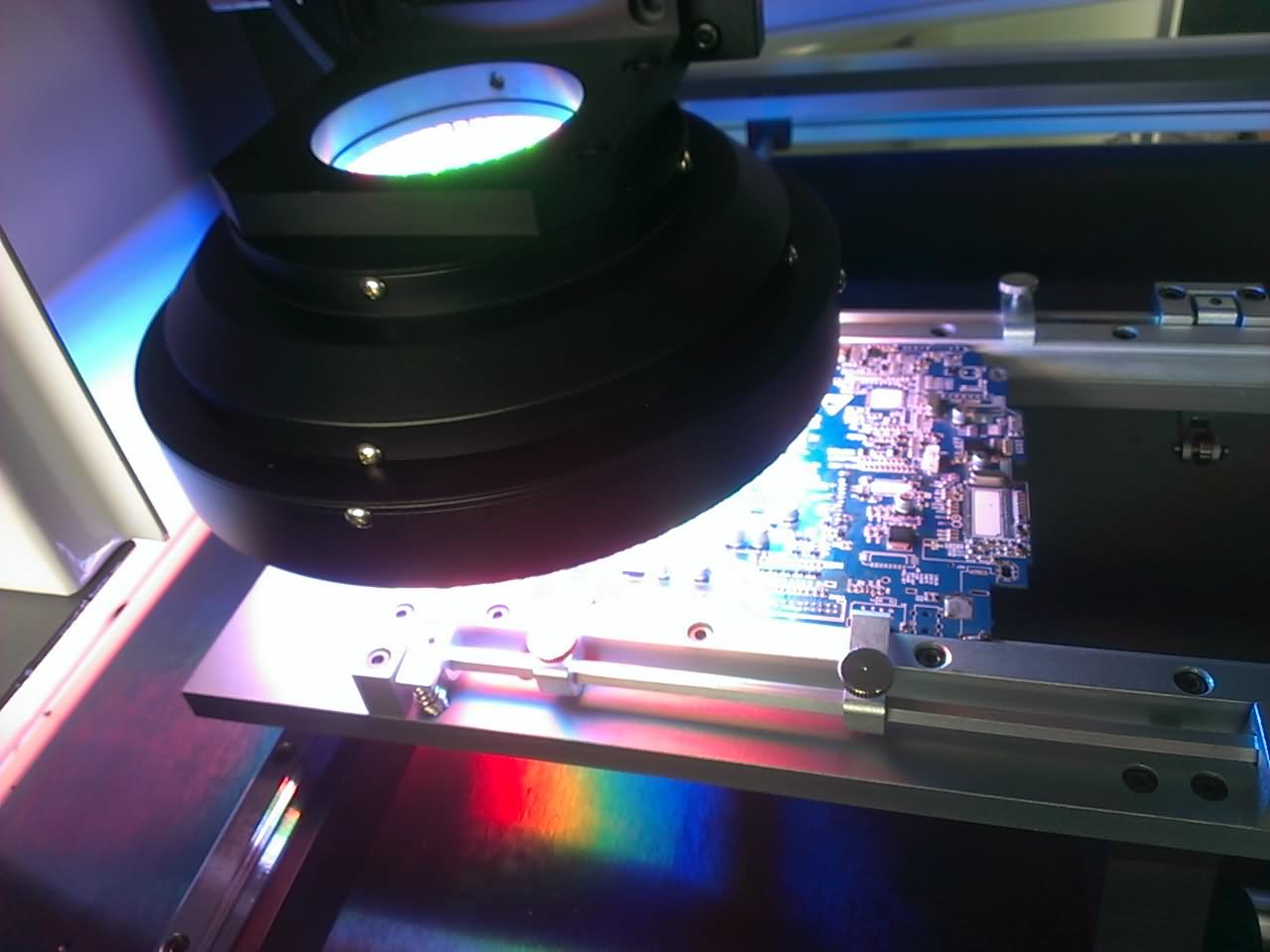

• Full-color high speed digital camera, ensure high efficiency, high quality and high stability of image shooting, restore the real and natural image effect.

• High cost-effective and practical.

• Annular stereo multi-channel color light, RGB/RGBW/RGBR/RWBR optional

• Lens resolution can be adjusted flexibly among 10-25um depends on different products.

• Accurate analysis of wave soldering points: excessive or missing solder, tin hole, bridge, IC pin defect, etc

Specifications EKT-VT-680:

| Inspection system | Application | After stencil printing, pre/post reflow oven, pre/post wave soldering |

| Program mode | Manual programming, auto programming, CAD data importing | |

| Inspection Items | Stencil printing: Solder unavailability, insufficient or excessive solder, solder misalignment, bridging, stain, scratch etc. | |

| Component defect: missing or excessive component, misalignment, uneven, edging, opposite mounting, wrong or bad component etc. | ||

| DIP: Missing parts, damage parts, offset, skew, inversion, etc | ||

| Soldering defect: excessive or missing solder, empty soldering, bridging, solder ball, IC NG ,copper stain etc. | ||

| Calculation Method | Machine learning, color calculation, color extraction, gray scale operation, image contrast | |

| Inspection mode | PCB fully covered, with array and bad marking function | |

| SPC statistics function | Fully record the test data and make analysis, with high flexibility to check production and quality status | |

| Minimum component | Missing parts, damage parts, offset, skew, sideways | |

| Optical system | Camera | 5 million pix full color high speed industrial digital camera |

| Lens resolution | 10um/15um/18um/20um/25um, can be customized base on need | |

| lighting source | Annular stereo multi-channel color light, RGB/RGBW/RGBR/RWBR optional | |

| Computer system | CPU | Intel Core |

| RAM | 4GB | |

| HDD | 500GB+ | |

| OS | Win XP 32bit | |

| Monitor | 22 inch,16:10 | |

| Mechanical system | Moving and inspection mode | Y servo motor driving PCB, X servo motor driving camera |

| PCB dimension | 20*20mm(Min)~450*350mm(Max), can be customized | |

| PCB thickness | 0.3~5.0mm | |

| PCB weight | Max:3KG | |

| PCB edge | 3mm,can be customized base on need | |

| PCB bending | <5mm or 3% of PCB Diagonal length | |

| PCB component height | Top:35mm,Bottom:75mmAdjustable, can be customized base on need | |

| XY driving system | AC servo motor, precise ball screw | |

| XY moving speed | Max:830mm/s | |

| XY positioning accuracy | ≦8um | |

| General parameters | Machine dimension | L1200 *W900 * H1500 mm |

| Power | AC220V,50/60Hz,1.2KW | |

| PCB height from ground | 820±20mm | |

| Machine weight | 420KG | |

| Safety standard | CE safety standard | |

| Environment temperature and humidity | 10~35℃,35~80% RH(non condensing) | |

| Optional | configuration | Maintenance station, offline programming system, SPC servo, bar code system |

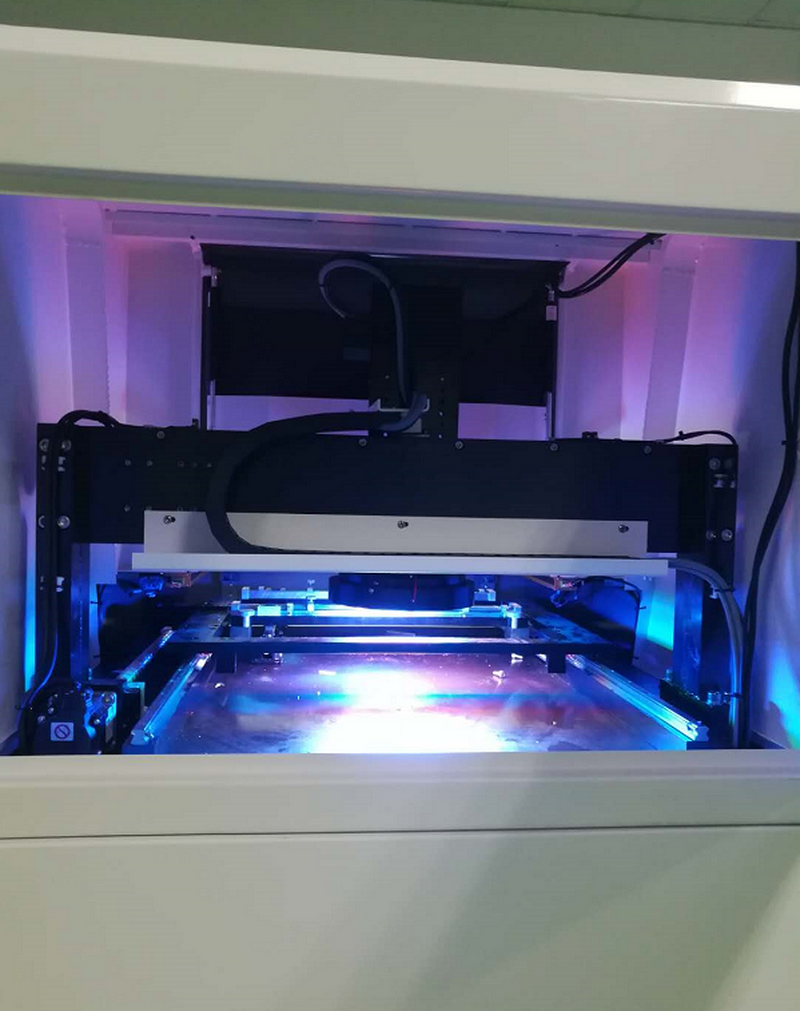

Product detail pictures:

Related Product Guide:

With this motto in mind, we have become one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for Quality Inspection for China Pcb Aoi Systems - Offline AOI EKT-VT-680 – Ektion , The product will supply to all over the world, such as: Morocco , New Zealand , Spain , "Create Values,Serving Customer!" is the aim we pursue. We sincerely hope that all customers will establish long term and mutually beneficial cooperation with us.If you wish to get more details about our company, You should contact with us now!

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!

Write your message here and send it to us