SMT is acronym for Surface Mount Technology, the most popular technology and process in the electronics assembly industry.

SPI is used for quality inspection of solder printing and validation and control of printing process after printing machine.SPI plays a considerable role in the whole SMT. The advantage of SPI is that it can detect printing defects in time before PCB placement, improve them, prevent them from flowing into the next process, reduce the cost of secondary repairs, and improve product quality. For example, When the camera detects that there is little tin or missing printing in a certain part of the printed solder paste, the machine can automatically fill the part with the little tin and complete tin tin filling. After that, it will be tested again to confirm that the tin amount after tin filling is normal before it can be released, which minimizes the cost of repair.

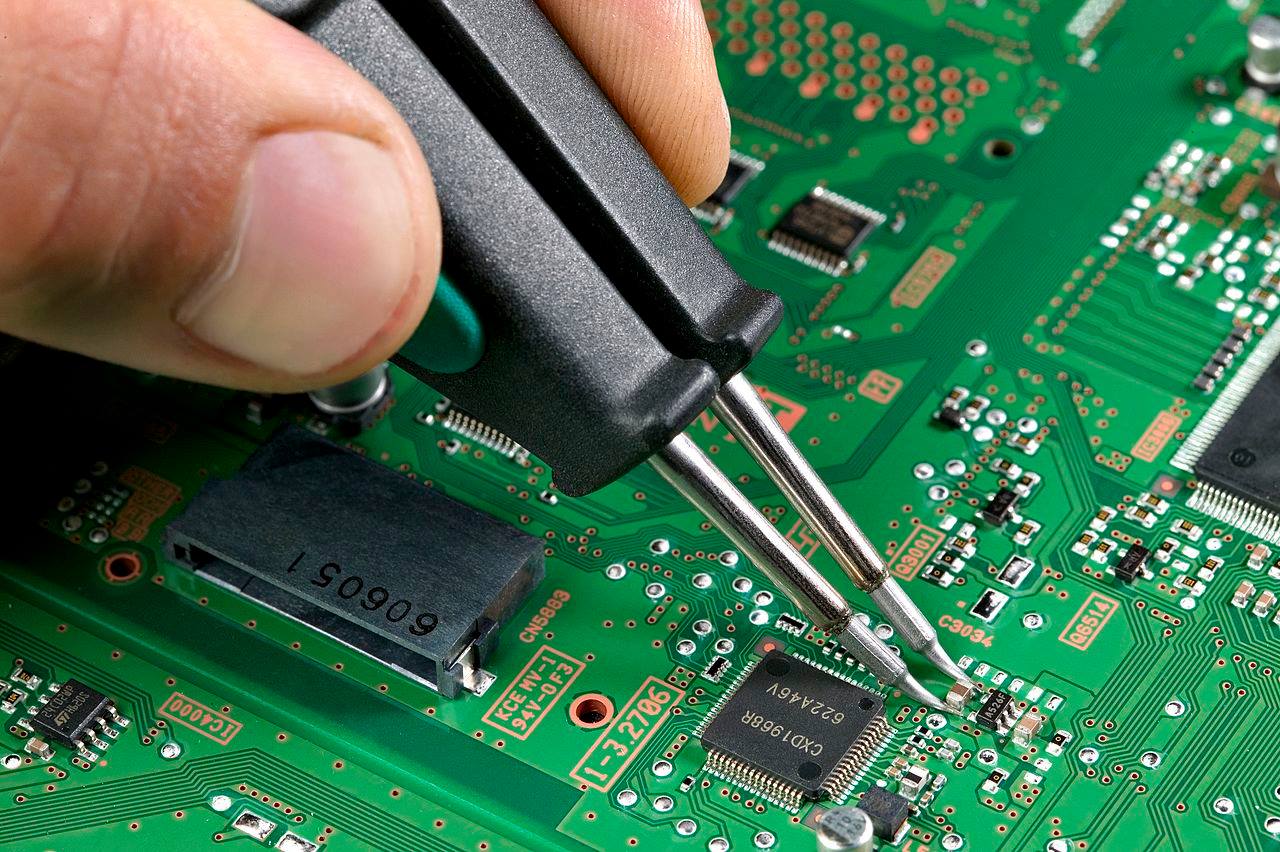

AOI is the abbreviation of automatic optical inspection, it’s used to detect various PCBA misfit and welding defects by high visual processing technology.AOI is divided into two types: before oven and after oven. The former detects components mount and the latter detects solder joint.

The two functions are different, SPI test solder paste printing,while AOI is to check the stability of mounted parts and welding quality.

Post time: Jan-13-2021