1、Basic principles of AOI technology

With the need of thin wireing of PCB conductor graphics, miniaturization of SMT devices and high density development of SMT components, automatic optical detection (AOI) technology has developed rapidly and has been widely used in SMT detection technology. The principle of AOI is the same as that of the visual system used in the placement machine and printing machine, usually using two methods of design rule inspection (DRC) and figure recognition. DRC method checks the circuit graphics according to some given rules (e.g. all wires should be end-points with solder joints, all pins width not less than 0.127 um, spacing between all pins not less than 0.102 mm, etc.). This method can guarantee the correctness of the tested circuit from the algorithm, and it is easy to manufacture, easy to realize high-speed processing of algorithm logic, small amount of program editing and small space of data. But this method has poor ability to determine the boundary, and the common pin inspection algorithm determines the boundary position according to the average value of the obtained pin, and determines the gray level according to the design. The graphic recognition method is to compare the stored digital image with the actual image. Check in accordance with a good piece of PCB or model-based inspection documents, or according to computer-aided design of the preparation of the inspection procedures . The accuracy depends on the resolution and the checking procedure used, which is generally the same as the electronic testing system, but the amount of data collected is large and the real-time processing of in real time. However, the graphic recognition method has obvious advantages in replacing the established design principles in the DRC with actual design data

2、 AOI Technology Detection Function

The AOI has the functions of component inspection, PCB light plate inspection, post-welding component inspection and so on. The general procedures for component detection AOI the monitoring system are: automatic counting of the PCB, of the installed components to start inspection; checking the PCB has a pin side to ensure that the pin end is arranged and bent properly; checking whether there are components missing, wrong components, damaged components, improper assembly direction of components on the front of the PCB; checking the type, direction and position of the installed IC discrete components; checking the quality inspection of marking printed on the device, etc. As soon as the AOI detects a defective component, the system signals the operator or triggers the actuator Structure automatically remove bad components. The system analyzes the defects, provides the main computer with the type and frequency of defects, and makes necessary adjustments to the manufacturing process. AOI inspection efficiency and reliability depend on the perfection of the software used. AOI also has the advantages of convenient use, easy adjustment, and no need to program for visual system algorithms. A typical AOI device and its detectable content are shown in Table 9-3.

3、 Composition and Principle of AOI System

Taking EKT inspection equipment as an example, the composition of AOI system is described, which is based on the AOI design rules, and the comparative checking function is added. two camera lenses are used, and the inspection system composition is shown in figure 9-1. A one-dimensional image sensor is used to image the printed line, and the resulting image signal is corrected and transmitted to the control subsystem A-D high-speed transformation. The control subsystem can judge the defects and scan the front and back of the inspection table so that the one-dimensional image sensor can get the two-dimensional (plane) graphic output signal. Check results are real-time and synchronized with the scan of ink in PCB The traps are marked, and the defects can be amplified in turn and displayed on the monitor, which can be checked visually. A system is operated in dialogue through a CRT display. The output subsystem consists of digital image monitor, entity image monitor, printer and synchronous oscilloscope. The digital color image and the entity image of the defect position are displayed on the monitor respectively, while printing the defect and a number. The synchronous oscilloscope can be used to observe the image signal and the digital limit level, and it is also easier to adjust the illumination and digital limit level. PI-2000 machines The maximum inspection speed is 1.24 m/min, high resolution, minimum pixel size is 10 um, with high resolution/low resolution two gear, can be switched. printing machine size is 500 mm*650mm*2 blocks. Minimum line width/line spacing um.160/80 There is no limit to the shape of the figure being examined.

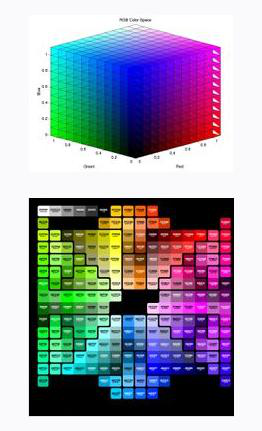

RGB color mode uses RGB model to assign an intensity value in the range 0~255 to the RGB component of each pixel in the image. And RGB images use only three colors to mix them in different proportions and present 16777216(255*255*255) colors on the screen,as shown below:

| Color | Red | Green | Blue |

| Black | 0 | 0 | 0 |

| Blue | 0 | 0 | 255 |

| Green | 0 | 255 | 0 |

| Cyan | 0 | 255 | 255 |

| Red | 255 | 0 | 0 |

| Magenta | 255 | 0 | 255 |

| Yellow | 255 | 255 | 0 |

| White | 255 | 255 | 255 |

The above colors are the common basic colors.

AOI detection, the color of each pixel of the component image taken by the camera is composed of RGB three different values, and the range of each value can be detected by RGB calculation.

The characteristics of color analysis and data analysis: AOI have a good detection rate of defects such as capacitance, IC and so on, which are more concentrated in color, and the programming and debugging are also very simple.

Post time: Jul-13-2020