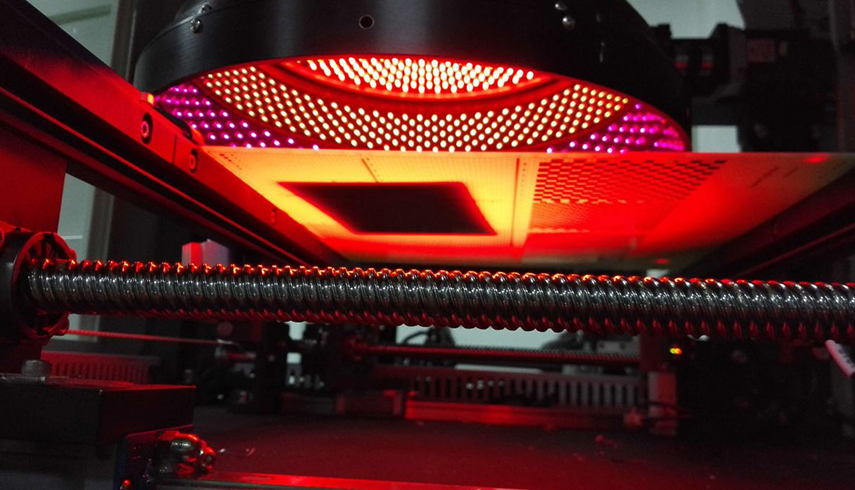

The AOI automatic optical inspection machine testing technology is a new type of testing technology that has only emerged in recent years; however, the technology has developed rapidly. At present, many manufacturers have introduced AOI testing equipment. In the automatic detection mode, the machine automatically scans the PCB through the camera, collects the images, compares the collected image data with the qualified parameters in the database, and after image processing, it checks for defects on the PCB; and then, defects are displayed or marked through the monitor or the automatic mark, so that the maintenance personnel can take repair measures.

The goal of implementing the AOI Automatic Optical Inspection Machine Testing Technology: The implementation of AOI has two main goals:

1. AOI (Automatic Optical Inspection) inspects the End Quality

It monitors the final state of the product as it exits the production line. When the production issues are very clear, product mix is high, and quantity and speed are the key factors, this goal is given top priority. AOI is usually placed in the middle of the production line. At this position, the device can generate a wide range of information on process control.

2. AOI (Automatic Optical Inspection) inspects the Process Tracking

Ektron: AOI automatic optical inspection machine testing technology employs inspection equipment to monitor the production process. It is typically a detailed defect classification. In the case that product reliability is important, low-mix and high-volume products are manufactured, this goal is given top priority by manufacturers. Through the inspection, it realizes online monitoring of specific production conditions, and provides the necessary basis for the adjustment of the production process.

Post time: Sep-24-2020