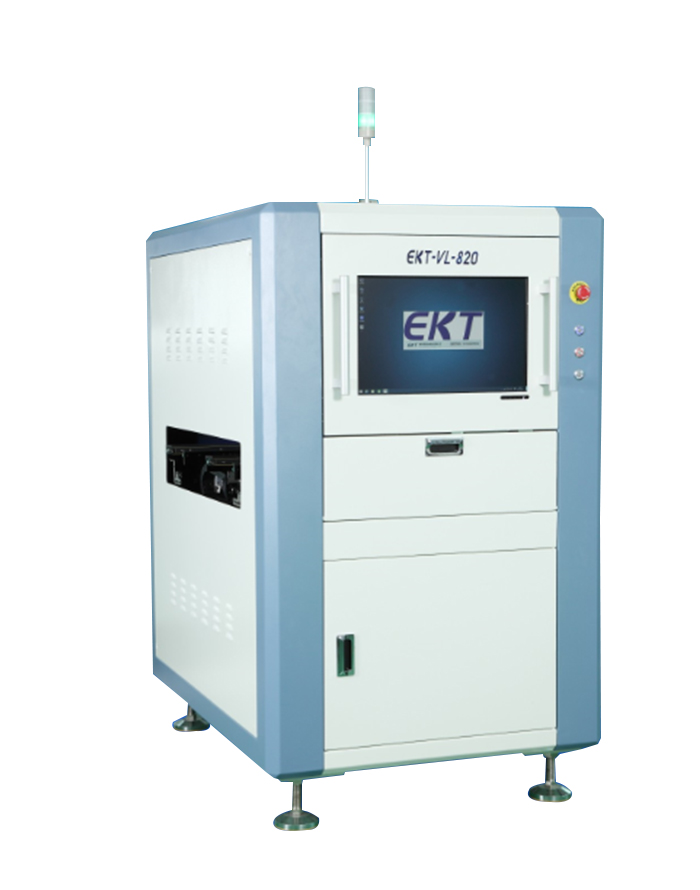

Manufacturer of Optical Inspection Aoi Supplier - Double rails online AOI EKT-VL-820 – Ektion

Manufacturer of Optical Inspection Aoi Supplier - Double rails online AOI EKT-VL-820 – Ektion Detail:

Product Detail:

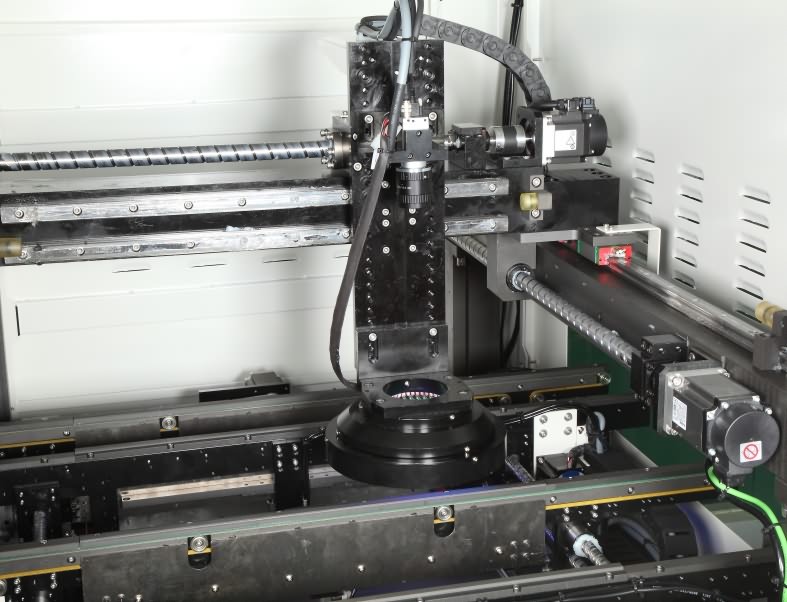

•One camera moving on XY direction, PCB transmitted by 2 conveyors.

•The 1st track fixed, the 2nd,3rd and 4th track adjustable.

•Applicable for various double conveyors production line.

•Fully compatible and retaining features of the series-8 single conveyor AOI products.

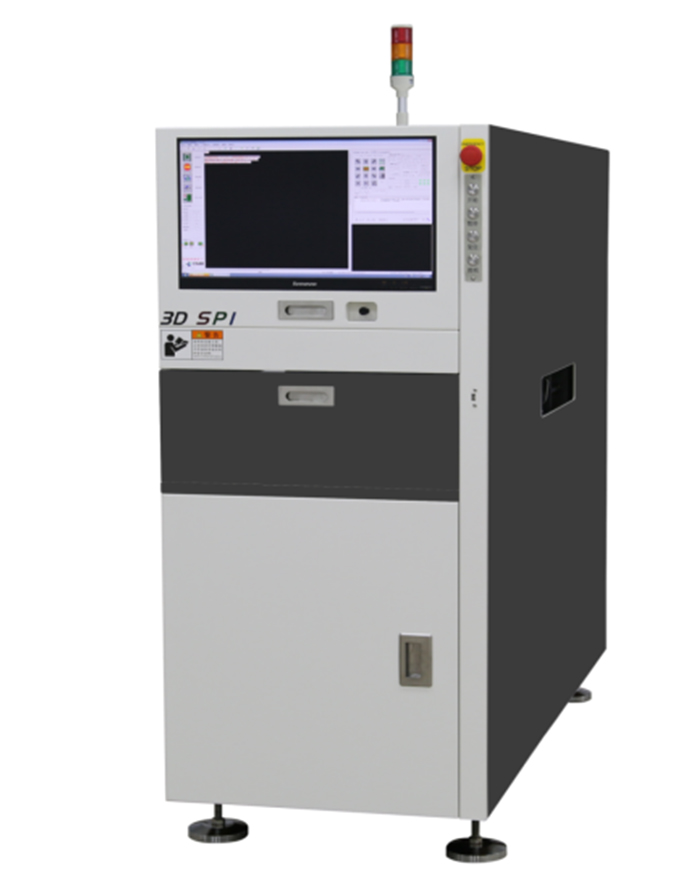

Double Conveyor Online AOI: EKT-VL-820

|

Inspection system |

Application |

After stencil printing, pre/post reflow oven, pre/post DIP wave soldering, FPC, etc |

|

Program mode |

Manual programming, auto programming, CAD data importing |

|

|

Inspection Items |

Stencil printing: Solder unavailability, insufficient or excessive solder, solder misalignment, bridging, stain, scratch etc. |

|

|

Component defect: missing or excessive component, misalignment, uneven, edging, opposite mounting, wrong or bad component etc. |

||

|

DIP :Missing parts, damage parts, offset, skew, inversion, etc |

||

|

Soldering defect: excessive or missing solder, empty soldering, bridging, solder ball, IC NG ,copper stain etc. |

||

|

Calculation Method |

Machine learning, color calculation, color extraction, gray scale operation, image contrast |

|

|

Inspection mode |

PCB fully covered, with array and bad marking function |

|

|

SPC statistics function |

Fully record the test data and make analysis, with high flexibility to check production and quality status. Image and test data saved simultaneously |

|

|

Components angle |

Angle 0~359°flexible,min angular distance 1° |

|

|

Min components |

01005 chip、0.3 pitch IC |

|

|

Optical system

|

Camera |

5 million pix full color high speed industrial digital camera, 20 million pix optional |

|

Lens resolution |

10um/15um/18um/20um/25um, can be custom-made |

|

|

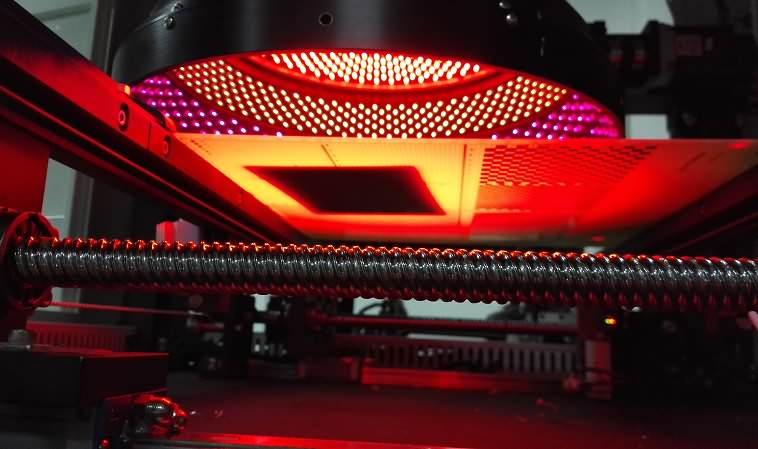

lighting source |

Annular stereo multi-channel color light, RGB/RGBW/RGBR/RWBR optional |

|

| Computer |

CPU |

Intel i7 3.40GHz |

|

GPU |

optional |

|

|

RAM |

16GB |

|

|

HDD |

1TB mechanical hard disk, SSD optional |

|

|

OS |

Win 7 64bit |

|

|

Monitor |

22 inch,16:10 (side sliding door) |

|

| Mechanical system |

Moving and inspection mode |

Stepping motor driving PCB auto-moving and width adjusting orbit; direction L-R or R-L optional; XY servo motor driving camera, double PCBA conveyor, width can be adjusted respectively. |

|

PCB size |

Both conveyor used:50*50mm(Min)~400*360mm(Max), single conveyor used: 50*50mm(Min)~460*650mm(Max), special size can be customized |

|

|

PCB thickness |

0.3~5.0mm |

|

|

PCB weight |

Max:3KG |

|

|

PCB edge |

3mm,special request can be custom made |

|

|

PCB bending |

Less than 5mm or 3% of PCB diagonal length |

|

|

PCB components height |

Top:35mm,Bottom:75mm. Can be adjustable and custom made |

|

|

XY driving system |

AC servo motor, precise ball screw |

|

|

XY moving speed |

Max:830mm/s |

|

|

XY accuracy deviation |

Less than 8um |

|

| General parameters |

Machine dimension |

L1440 * W1000 * H1620 mm, |

|

Power |

AC220V,50/60Hz,2KW |

|

|

PCB height from ground |

900±20mm |

|

|

Machine weight |

700KG |

|

|

Equipment communications |

Smema |

|

|

Air pressure |

0.4-0.8MPa,can adapt electronic control to avoid pressure limit |

|

|

Safety standard |

CE standard |

|

|

Environment temperature and humidity |

10~35℃,35~80% RH (non condensing)

|

|

|

|

Optional function |

Maintenance station system, offline programming system, SPC server system,bar code identification system |

Product detail pictures:

Related Product Guide:

We've got a specialist, effectiveness staff to supply high quality service for our shopper. We always follow the tenet of customer-oriented, details-focused for Manufacturer of Optical Inspection Aoi Supplier - Double rails online AOI EKT-VL-820 – Ektion , The product will supply to all over the world, such as: Hungary , London , Miami , We strive for excellence, constant improvement and innovation, is committed to make us the "customer trust" and the "first choice of engineering machinery accessories brand" suppliers. Choose us, sharing a win-win situation!

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.