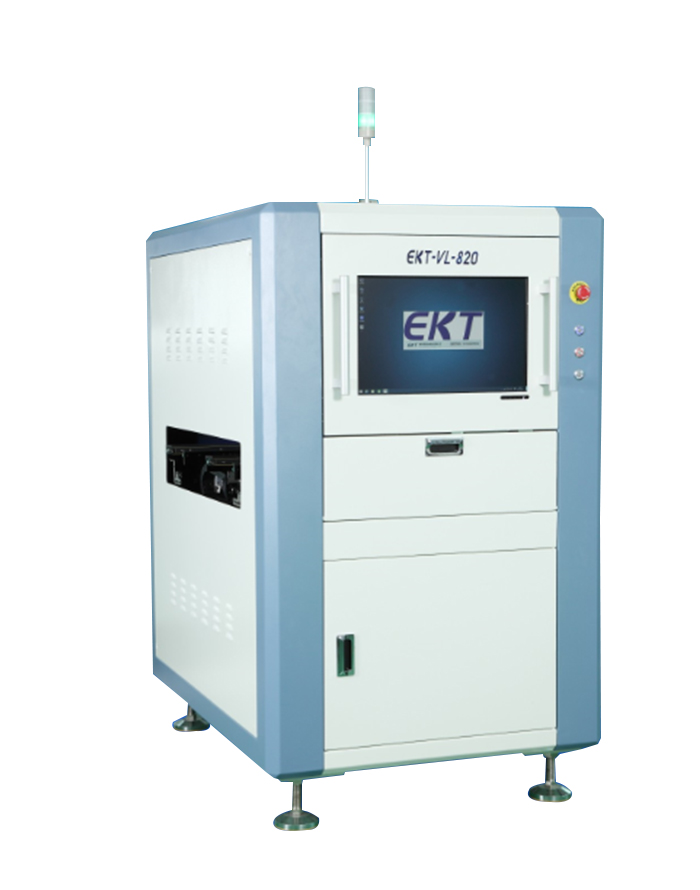

High Quality PCB Automatic Optical Inspection Machine - Desktop reflow soldering – Ektion

High Quality PCB Automatic Optical Inspection Machine - Desktop reflow soldering – Ektion Detail:

Model:RF-300-LS

|

Specifications:

| Description | Desktop reflow soldering |

| Model | RF-300-LS |

| Heating zone | 3 |

| Heating zone length | 1000mm |

| Heating model | The hot air circulation |

| Cooling zone | 1 |

| Maximum width PCB | 300mm |

| The transport direction | eft, right or right to left |

| The transport belt height | 880±20mm |

| Transmission mode | Network transmission |

| Conveyor speed | 0-2000mm/min |

| Power Supply | The 5 line 3 phase 380V or phase 220v50/60Hz |

| Start power | 4Kw |

| Normal working power | Approx1.5Kw |

| Heating time | About 10 minutes |

| Temperature control range | The room temperature~320℃ |

| Temperature control mode | PID closed-loop control |

| The precision of temperature control | ±1℃ |

| Bias temperature distribution of PCB plate | ±2℃ |

| Abnormal alarm | Temperature anomalies |

| Overall dimensions (length * width * height) | L1400×W612×H650 |

| The weight of the machine | Approx160Kg |

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of High Quality PCB Automatic Optical Inspection Machine - Desktop reflow soldering – Ektion , The product will supply to all over the world, such as: Mexico , Czech republic , Paraguay , Our products are widely recognized and trusted by users and can meet continuously changing of economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.

Write your message here and send it to us