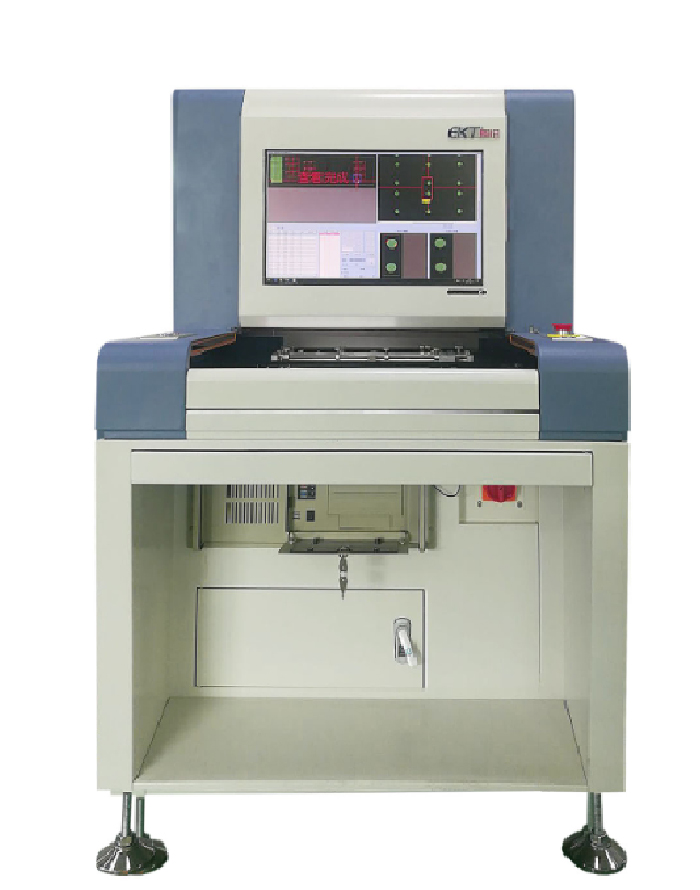

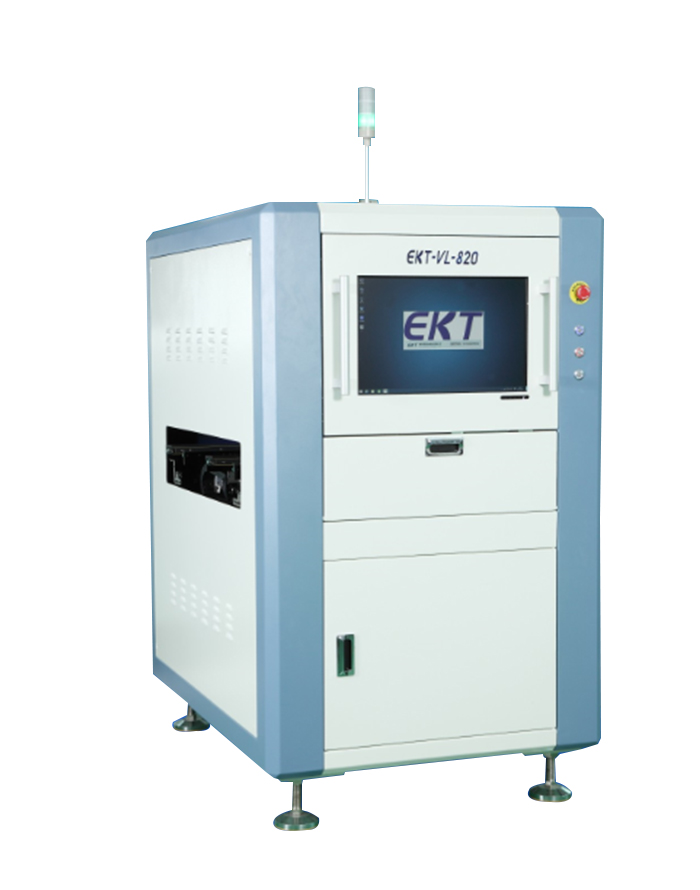

High Quality PCB Assembly Inspection Solutions - Double rails online AOI EKT-VL-820 – Ektion

High Quality PCB Assembly Inspection Solutions - Double rails online AOI EKT-VL-820 – Ektion Detail:

Product Detail:

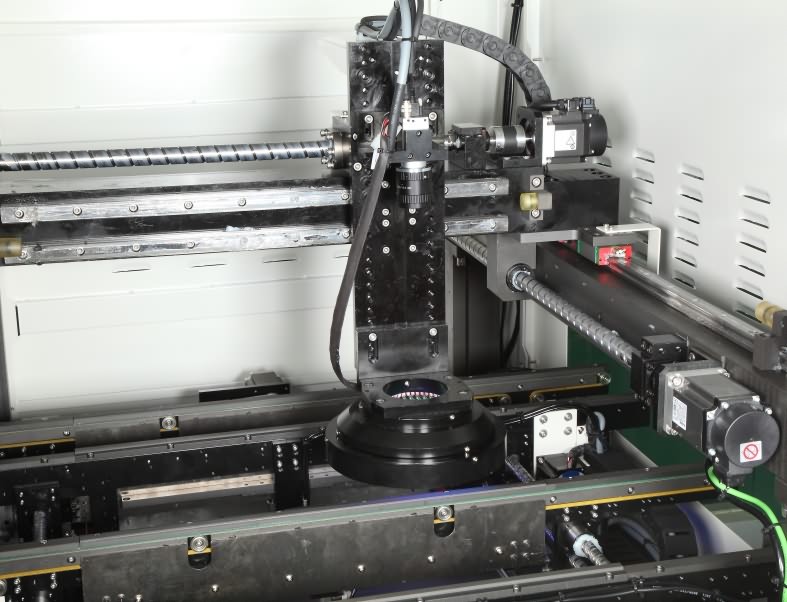

•One camera moving on XY direction, PCB transmitted by 2 conveyors.

•The 1st track fixed, the 2nd,3rd and 4th track adjustable.

•Applicable for various double conveyors production line.

•Fully compatible and retaining features of the series-8 single conveyor AOI products.

Double Conveyor Online AOI: EKT-VL-820

|

Inspection system |

Application |

After stencil printing, pre/post reflow oven, pre/post DIP wave soldering, FPC, etc |

|

Program mode |

Manual programming, auto programming, CAD data importing |

|

|

Inspection Items |

Stencil printing: Solder unavailability, insufficient or excessive solder, solder misalignment, bridging, stain, scratch etc. |

|

|

Component defect: missing or excessive component, misalignment, uneven, edging, opposite mounting, wrong or bad component etc. |

||

|

DIP :Missing parts, damage parts, offset, skew, inversion, etc |

||

|

Soldering defect: excessive or missing solder, empty soldering, bridging, solder ball, IC NG ,copper stain etc. |

||

|

Calculation Method |

Machine learning, color calculation, color extraction, gray scale operation, image contrast |

|

|

Inspection mode |

PCB fully covered, with array and bad marking function |

|

|

SPC statistics function |

Fully record the test data and make analysis, with high flexibility to check production and quality status. Image and test data saved simultaneously |

|

|

Components angle |

Angle 0~359°flexible,min angular distance 1° |

|

|

Min components |

01005 chip、0.3 pitch IC |

|

|

Optical system

|

Camera |

5 million pix full color high speed industrial digital camera, 20 million pix optional |

|

Lens resolution |

10um/15um/18um/20um/25um, can be custom-made |

|

|

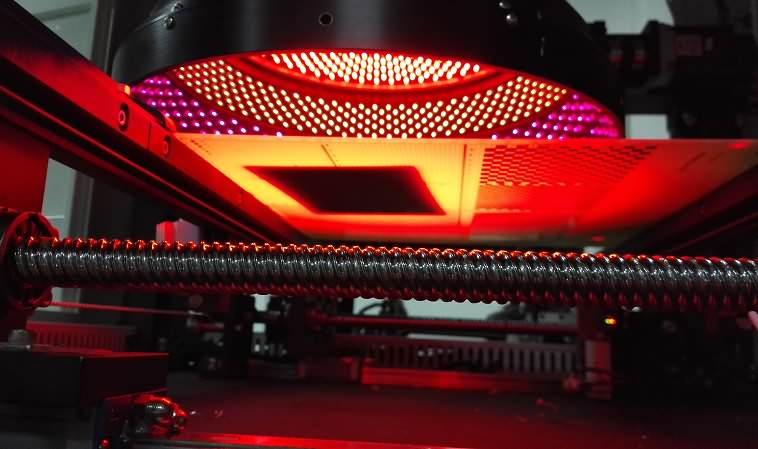

lighting source |

Annular stereo multi-channel color light, RGB/RGBW/RGBR/RWBR optional |

|

| Computer |

CPU |

Intel i7 3.40GHz |

|

GPU |

optional |

|

|

RAM |

16GB |

|

|

HDD |

1TB mechanical hard disk, SSD optional |

|

|

OS |

Win 7 64bit |

|

|

Monitor |

22 inch,16:10 (side sliding door) |

|

| Mechanical system |

Moving and inspection mode |

Stepping motor driving PCB auto-moving and width adjusting orbit; direction L-R or R-L optional; XY servo motor driving camera, double PCBA conveyor, width can be adjusted respectively. |

|

PCB size |

Both conveyor used:50*50mm(Min)~400*360mm(Max), single conveyor used: 50*50mm(Min)~460*650mm(Max), special size can be customized |

|

|

PCB thickness |

0.3~5.0mm |

|

|

PCB weight |

Max:3KG |

|

|

PCB edge |

3mm,special request can be custom made |

|

|

PCB bending |

Less than 5mm or 3% of PCB diagonal length |

|

|

PCB components height |

Top:35mm,Bottom:75mm. Can be adjustable and custom made |

|

|

XY driving system |

AC servo motor, precise ball screw |

|

|

XY moving speed |

Max:830mm/s |

|

|

XY accuracy deviation |

Less than 8um |

|

| General parameters |

Machine dimension |

L1440 * W1000 * H1620 mm, |

|

Power |

AC220V,50/60Hz,2KW |

|

|

PCB height from ground |

900±20mm |

|

|

Machine weight |

700KG |

|

|

Equipment communications |

Smema |

|

|

Air pressure |

0.4-0.8MPa,can adapt electronic control to avoid pressure limit |

|

|

Safety standard |

CE standard |

|

|

Environment temperature and humidity |

10~35℃,35~80% RH (non condensing)

|

|

|

|

Optional function |

Maintenance station system, offline programming system, SPC server system,bar code identification system |

Machine characteristics

High-precision, full-color vision technology

Offline programming, offline debugging function

Jigsaw and Multi Mark (including Bad Mark function)

High-quality hardware configuration, simple and stable machine

Powerful SPC software function, real-time quality analysis

Multiple detection algorithm with high detection rate and low false positive rate

Automatic recognition of Barcode and OCR text recognition by camera

Can be used in multiple positions after printing, in front of the furnace, behind the furnace, etc.

Based on CAD data, automatically search component library to realize automatic programming

Remote control system connected via wired or wireless network

Strong performance

Strong performance

1. Deep learning technology + GPU processing technology, strong matching of black technology, ultra-high detection rate, extremely low misjudgment rate, and performance improvement of up to 70% compared with the previous generation.

2. More customized 140FPS ultra-high-speed camera + customized telecentric lens + fifth-generation composite tower-shaped LED coaxial light source, image capture and data transmission are as fast as lightning. Whether it is small component recognition, fuzzy silk screen recognition, high component recognition, you can see at a glance.

3. The new generation of products are smarter, simpler, more stable, and more user-friendly. The programming and debugging time is greatly shortened, and the efficiency is rising linearly.

4. The new generation of products breaks through the shackles of performance again, greatly reduces misjudgments, and reduces the workload of manual re-judgment, which greatly improves the control of one person and multiple lines. For example, the original one person can control four lines. 1 person controls 8 lines.

Intelligent Control Center

1 The cumbersome programming and debugging process has always been the main reason why engineers are tired of using AOI, and it is also the bottleneck of efficient production. Quick programming and quick change of models are symbols of high-end AOI. ALD7720S has a variety of fast programming modes. By importing CAD data, it can automatically link to public standards or specification templates to complete the program, quickly responding to the testing needs of new models. It can be applied to large, medium and small production modes and product types.

2 Based on the improvement of efficiency, in addition to the i-series processors and multi-threaded processing, the latest non-stop programming and debugging technology has been developed. Users can remotely complete the program optimization of multiple production lines without suspending the operation of the machine to achieve both detection and programming. Increase production capacity.

3 The maintenance station is connected with AO1 through the network cable and HUB. You can choose one repair station to one AOI, multiple repair stations to multiple AOl, and one repair station to multiple AOI modes to view the test results.

The AOI equipment will transmit the inspection data to Repair Station in real time during the production process. According to the operator’s judgment, AOI automatically sends OK and NG signals, which are sent to different TRAYs, so as to realize fully automated process control, and one person controls multiple lines.

Product detail pictures:

Related Product Guide:

We are ready to share our knowledge of marketing worldwide and recommend you suitable products at most competitive prices. So Profi Tools offer you best value of money and we are ready to develop together with High Quality PCB Assembly Inspection Solutions - Double rails online AOI EKT-VL-820 – Ektion , The product will supply to all over the world, such as: El Salvador , Nepal , Nigeria , Each customer's satisfactory is our goal. We are looking for long-term cooperation with each customer. To meet this, we keep up our quality and provide extraordinary customer service. Welcome to our company, we are expecting to cooperate with you.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.