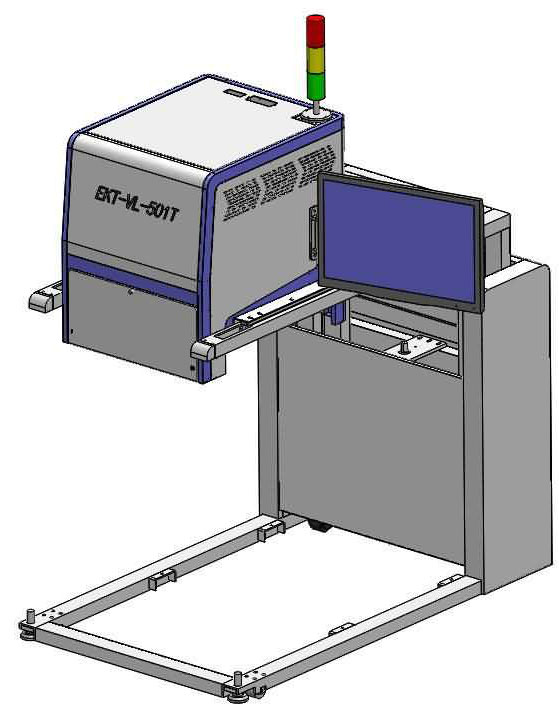

High Quality PCB AOI - Overal-view DIP online AOI EKT-VL-501T – Ektion

High Quality PCB AOI - Overal-view DIP online AOI EKT-VL-501T – Ektion Detail:

• Modular structure, easy to install and move.

• Apply to various production line flexibly, no disturb for the state of original production line.

• Common inspection items: wrong/missing/offset of components, barcode, packing inspection, etc.

• Automatically select the optimal combination effect of camera, lens and light source.

• Test result stored and summarized in SPC, with auto-alarming system.

• Compatible with functions of series 8 products.

• 20 million pix camera, high resolution lens.

Specifications EKT-VL-501T:

|

|

|

Overall-view DIP online AOI EKT-VL-501T |

|

Inspection system |

Application |

Pre/post DIP wave soldering |

|

Program mode |

Manual programming, auto programming, CAD data importing, offline programming |

|

|

Inspection Items |

DIP :Missing parts, damage parts, offset, skew, inversion, etc |

|

|

Calculation Method |

Machine learning, color calculation, color extraction, gray scale operation, image contrast |

|

|

Inspection mode |

Single lens covers whole PCBA to inspect, fast speed, support continuous detection without pause, support collating board inspection and multi-mark, support various board on same line, with function of bad mark. |

|

|

Result display |

Online support 20 boards result cache display, support database plug-in display, NG result voice broadcasting. |

|

|

SPC statistics function |

Fully record the test data and make analysis,,with high flexibility to check production and quality status. Inspected picture and data saved synchronously by serial number. |

|

| Component angle |

Support 0~359° rotation,minimum angular distance 1° |

|

| Minimum component |

1 mm |

|

| Optical system

|

Camera |

High-speed global exposure industrial digital camera 20million pix camera,support shooting in motion |

|

Lens resolution |

10um/15um/18um/20um/25um,can be customize |

|

|

lighting source |

Top and side LED lighting board |

|

|

Computer system |

CPU |

Intel i7 or same level |

|

RAM |

8GB |

|

|

SSD |

128GB |

|

|

OS |

Win7 64bit |

|

|

Monitor |

22inch ,16:10 |

|

|

Mechanical system |

Moving and inspection mode |

PCB board moving controlled by customer production line. Support rail conveyor and belt line, automatic correction for bias and angle by pcb mark positioning. |

|

PCB dimension |

50*50mm(Min)~500*500mm(Max), can be customized |

|

|

PCB thickness |

0.3~5.0mm |

|

|

PCB weight |

Max:3KG |

|

|

Production line speed |

Max : 3.5m /min |

|

|

PCB edge |

3mm,can be customized base on need |

|

|

PCB bending |

<5mm,or 3% of PCB Diagonal length |

|

|

PCB component height |

50mm,adjustable,can be customized base on need |

|

|

General parameters |

Machine dimension |

L710mm * W600mm * H700 mm,height does not include signal light |

|

Power |

AC220V,50/60Hz,1.0KW |

|

|

PCB height from ground |

Not limited,AOI directly working on production line |

|

|

Machine weight |

90KG |

|

|

Safety standard |

CE safety standard |

|

|

Environment temperature and humidity |

10~35℃,35~80% RH(non condensing)

|

|

|

|

Optional configuration |

Maintenance station, offline programming system, SPC servo, bar code system |

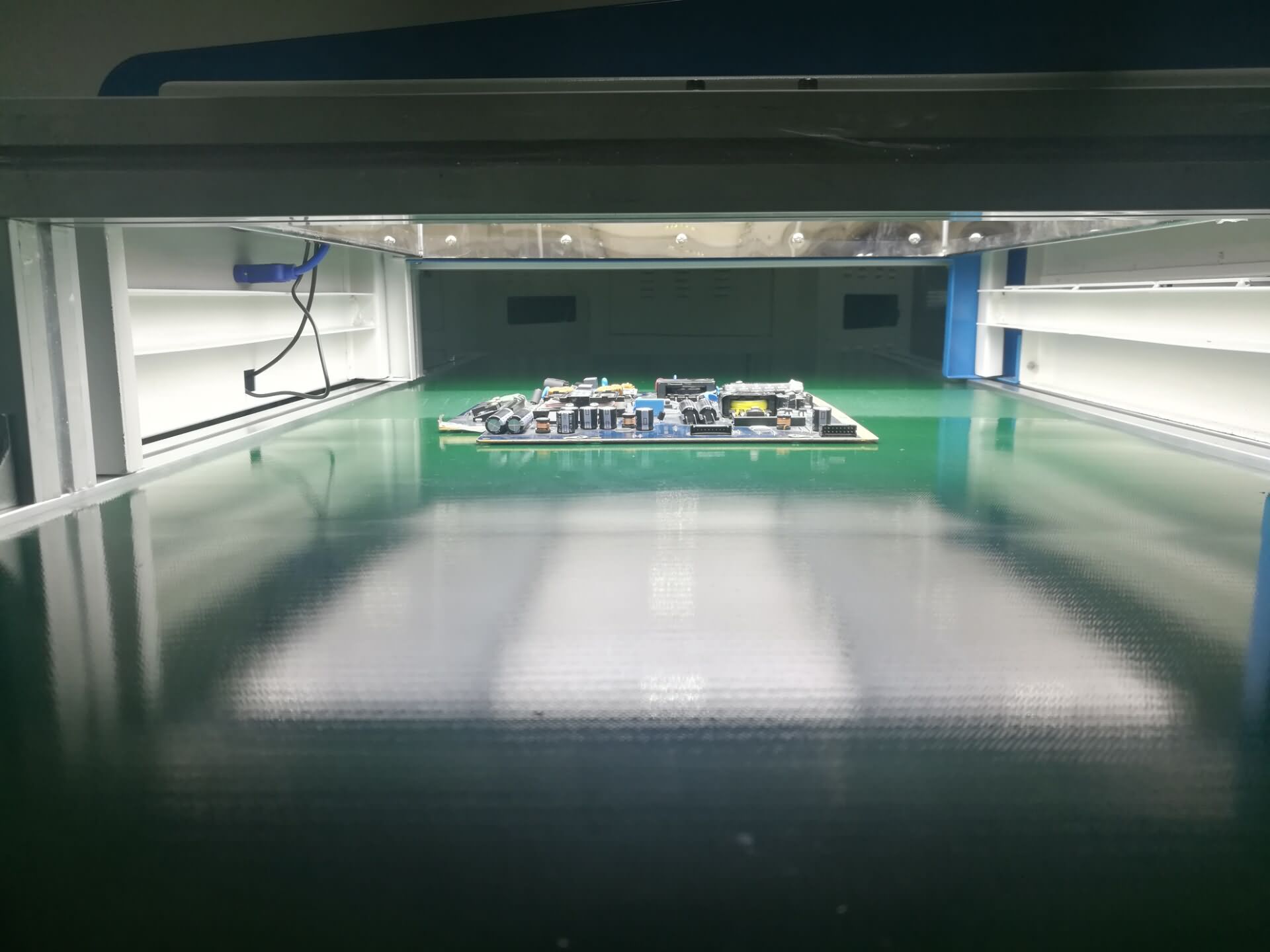

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" may be the persistent conception of our organization to the long-term to build together with shoppers for mutual reciprocity and mutual advantage for High Quality PCB AOI - Overal-view DIP online AOI EKT-VL-501T – Ektion , The product will supply to all over the world, such as: Lebanon , Zurich , Tanzania , To create more creative products, maintain high-quality products and update not only our products but ourselves so as to keep us ahead of the world, and the last but most vital one: to make every client satisfied with everything we offer and to grow stronger together. To be the real winner, starts here!

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.