China OEM Automatic Optical Inspection Product - Double cameras online AOI EKT-VL-800D – Ektion

China OEM Automatic Optical Inspection Product - Double cameras online AOI EKT-VL-800D – Ektion Detail:

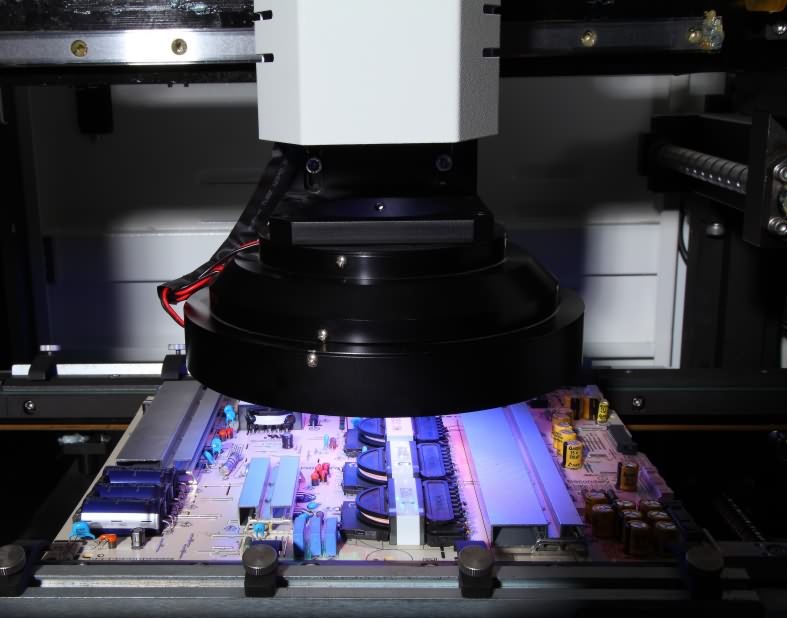

• Top and bottom double cameras, each has independent XY moving platform.

• Top camera used to inspect insertion components, while bottom camera used to inspect wave soldering surface, two surface inspected simultaneously.

• Fully compatible and retaining features of the series-8 single conveyor AOI products.

Specifications: EKT-VL-800D

| Inspection system | Application | After stencil printing, pre/post reflow oven, pre/post wave soldering, FPC |

| Program mode | Manual programming, auto programming, CAD data importing | |

| Inspection Items | Stencil printing: Solder unavailability, insufficient or excessive solder, solder misalignment, bridging, stain, scratch etc. | |

| Component defect: missing or excessive component, misalignment, uneven, edging, opposite mounting, wrong or bad component etc. | ||

| DIP: Missing parts, damage parts, offset, skew, inversion, etc | ||

| Soldering defect: excessive or missing solder, empty soldering, bridging, solder ball, IC NG ,copper stain etc. | ||

| Calculation Method | Machine learning, color calculation, color extraction, gray scale operation, image contrast, OCV/OCR etc. | |

| Inspection mode | PCBA top and bottom inspected simultaneously by 2 cameras, PCB fully covered, with array and bad marking function | |

| SPC statistics function | Fully record the test data and make analysis, with high flexibility to check production and quality status | |

| Minimum component | 01005 chip,0.3pitch IC | |

| Optical system | Cameras | 2 cameras, top and bottom, 5million pix full color high speed industrial digital camera |

| Lens resolution | 10um/15um/18um/20um/25um, can be customized base on need | |

| lighting source | Annular stereo multi-channel color light, RGB/RGBW/RGBR/RWBR optional | |

| Computer system | CPU | Intel E3 or same level |

| RAM | 16GB | |

| HDD | 1TB , SSD optional | |

| OS | Win 7 64bit | |

| Monitor | 22 inch,16:10 | |

| Mechanical system | Moving and inspection mode | 2 sets of XY servo motors drive cameras and step motor drives PCB rail, PCB rail adjustable . Moving direction L-R/R-L optional. |

| PCB dimension | 50*50mm(Min)~400*360mm(Max), can be customized | |

| PCB thickness | 0.3~5.0mm | |

| PCB weight | Max:3KG | |

| PCB edge | 3mm,can be customized base on need | |

| PCB bending | <5mm or 3% of PCB diagonal length | |

| PCB component height | Top:35mm,Bottom:35mmAdjustable, can be customized base on need | |

| XY driving system | AC servo motor, precise ball screw | |

| XY moving speed | Max:830mm/s | |

| XY positioning accuracy | ≦8um | |

| General parameters | Machine dimension | L1120 * W980 * H1700 mm |

| Power | AC220V,50/60Hz,2.5KW | |

| PCB height from ground | 900±20mm | |

| Machine weight | 780KG | |

| Connection with other SMT machine | Smema | |

| Air pressure | 0.4 – 0.8MPa | |

| Safety standard | CE safety standard | |

| Environment temperature and humidity | 10~35℃,35~80% RH(non condensing) | |

| Optional | configuration | Maintenance station, offline programming system, SPC servo, bar code system |

Product detail pictures:

Related Product Guide:

The really abundant projects management experiences and 1 to just one provider model make the high importance of business enterprise communication and our easy understanding of your expectations for China OEM Automatic Optical Inspection Product - Double cameras online AOI EKT-VL-800D – Ektion , The product will supply to all over the world, such as: Montreal , Georgia , Lithuania , Due to our good goods and services, we've received good reputation and credibility from local and international customers. If you will need more information and are interested in any of our solutions, be sure to feel free to contact us. We look forward to becoming your supplier in the near future.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.

Write your message here and send it to us