Cheap Optical Inspection System - Full Automatic / Semi Automatic online / SMT AOI Machine for PCB Assembly Line – Ektion

Cheap Optical Inspection System - Full Automatic / Semi Automatic online / SMT AOI Machine for PCB Assembly Line – Ektion Detail:

Introduction of AOI

The full name of AOI (Automatic Optic Inspection) is bai automatic optical inspection, du is a device that detects common defects encountered in welding production based on optical principles. AOI is a new type of testing technology that is emerging, but it is developing rapidly, and many manufacturers have introduced AOI testing equipment. During automatic inspection, the machine automatically scans the PCB through the camera, collects images, compares the tested solder joints with the qualified parameters in the database, after image processing, checks out the defects on the PCB, and displays/marks the defects through the display or automatic signs Come out for repair by maintenance personnel. area of interest The name of the research area in some software of remote sensing and geographic information system. Use high-speed and high-precision visual processing technology to automatically detect various mounting errors and welding defects on the PCB board. PCB boards can range from fine-pitch high-density boards to low-density large-size boards, and can provide online inspection solutions to improve production efficiency and welding quality. By using AOI as a tool to reduce defects, errors can be found and eliminated early in the assembly process to achieve good process control. Early detection of defects will avoid sending bad boards to the subsequent assembly stage. AOI will reduce repair costs and avoid scrapping unrepairable circuit boards.

How does AOI work?

The full name of AOI (Automatic Optic Inspection) is bai automatic optical inspection, which is based on the optical principle du to detect common defects encountered in zhi welding production. AOI is a new type of testing technology that is emerging, but it is developing rapidly, and many manufacturers have introduced AOI testing equipment. During automatic inspection, the machine automatically scans the PCB through the camera, collects images, compares the tested solder joints with the qualified parameters in the database, after image processing, checks out the defects on the PCB, and displays/marks the defects through the display or automatic signs Come out and be repaired by maintenance personnel.

area of interest The name of the research area in some software of remote sensing and geographic information system. Use high-speed and high-precision visual processing technology to automatically detect various mounting errors and welding defects on the PCB board. PCB boards can range from fine-pitch high-density boards to low-density large-size boards, and can provide online inspection programs to improve production efficiency and welding quality. By using AOI as a tool to reduce defects, errors can be found and eliminated early in the assembly process to achieve good process control. Early detection of defects will avoid sending bad boards to the subsequent assembly stage, AOI will reduce repair costs and avoid scrapping unrepairable circuit boards.

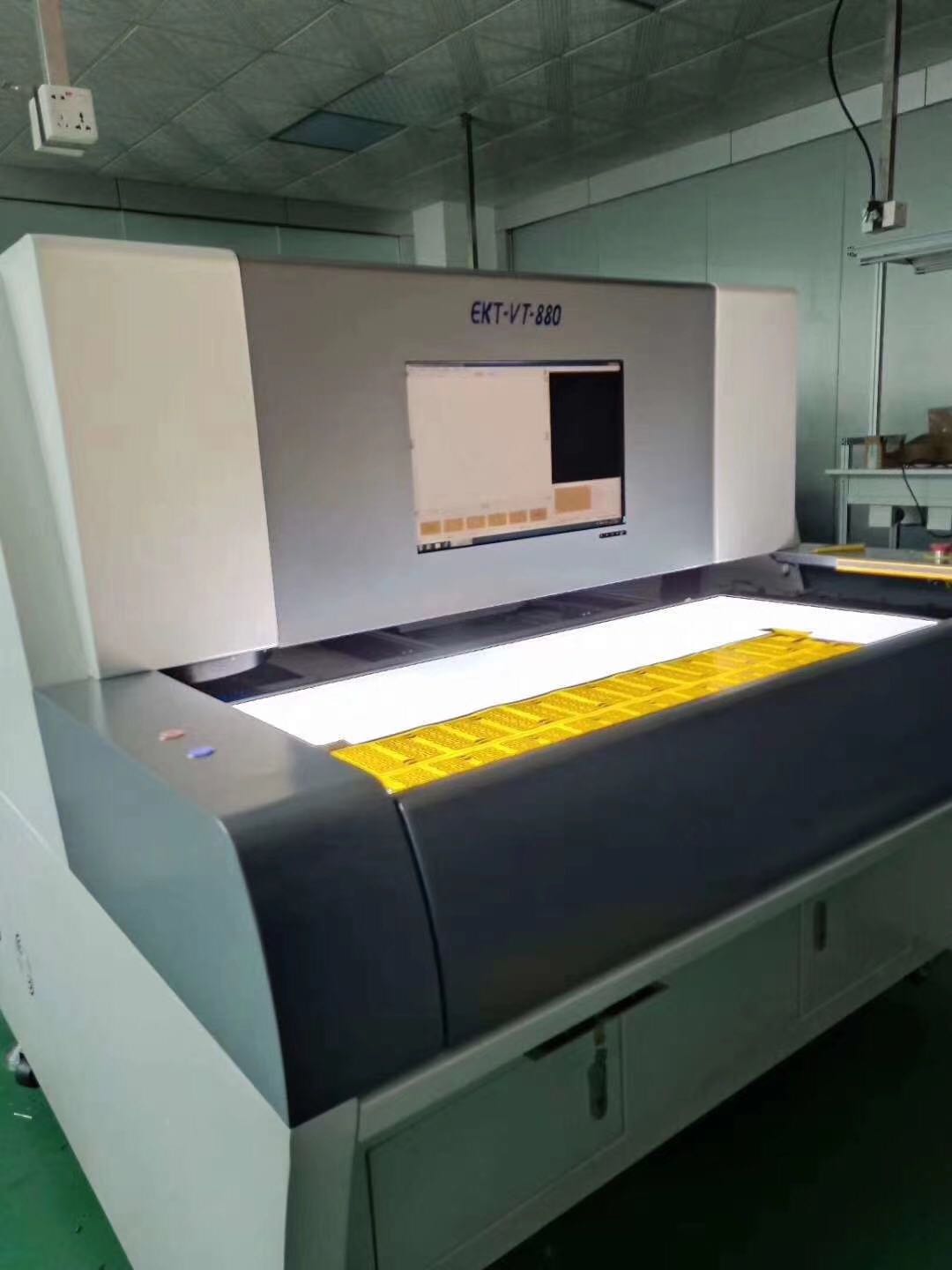

Product detail pictures:

Related Product Guide:

Often customer-oriented, and it's our ultimate target to become not only probably the most reputable, trustable and honest provider, but also the partner for our customers for Cheap Optical Inspection System - Full Automatic / Semi Automatic online / SMT AOI Machine for PCB Assembly Line – Ektion , The product will supply to all over the world, such as: Macedonia , Luxembourg , Rome , Our main objectives are to provide our customers worldwide with good quality, competitive price, satisfied delivery and excellent services. Customer satisfaction is our main goal. We welcome you to visit our showroom and office. We are looking forward to establish business relation with you.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.