Cheap AOI Inspection System - Full Automatic Multi-function Pick Place Machine – Ektion

Cheap AOI Inspection System - Full Automatic Multi-function Pick Place Machine – Ektion Detail:

Use the most convenient positioning block, base plate origin positioning method to fix position. The Positioning is highly accurate (Precision less than 0.05 mm). Mounting angle range 0-360° and the precision is 0.1°. Every picking nozzle is an independent rotation angle, moreover added 6 cameras of components recognition. In addition to place the traditional long led tube light, also can place bulb light, down light, spot light, ceiling light, LED fence light, LED driving power supply, copper wire string light and so on.

Specifications:

| Product name | EKT560EKT560 Full automatic multi-function pick place machine |

| Maximum PCB area | 500×400mm |

| Maximum moving range | X axis 500mm, Y axis 400mm |

| Z axis Maximum moving range | 12mm |

| Max placement speed | 30000CPH |

| Typical placement speed | 20000CPH |

| Movement precision | ±0.05mm |

| Positioning method | MARK point camera + 6 sets Sony visual camera position+1 set industrial camera |

| Can mount components | 0603 upper resistor and capacitor parts and LED chips 3528, 5050, meanwhile meet requirement of SOP, SOT chip placement, power driver, control board etc placement and compatible with all kinds of high power chip mount. |

| Types of production | LED tube light, soft LED strip light, power supply driver, fence light, display module, switch, display screen etc multi LED application products |

| Programming method | Automatic Visual camera Positioning programming |

| Belt type feeder | 8mm, 12mm, 16mm, and 24mm feeder |

| Number of feeders | can install 45pcs of standard 8mm feeder |

| Operating system | WINDOWS 7 |

| Compressed air | 0.55MPA |

| Power supply | 220V, 50Hz, 2.0KW |

| Weight | 1000Kg |

| Dimension | 1300MM(L)*1300MM(W)*1450MM(H) |

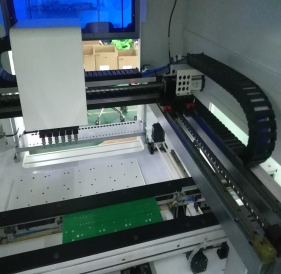

Product detail pictures:

Related Product Guide:

Our commission should be to provide our customers and consumers with ideal top quality and aggressive portable digital products for Cheap AOI Inspection System - Full Automatic Multi-function Pick Place Machine – Ektion , The product will supply to all over the world, such as: US , Paraguay , Grenada , To win customers' confidence, Best Source has set up a strong sales and after-sales team to deliver the best product and service. Best Source abides by the idea of "Grow with customer" and philosophy of "Customer-oriented" to achieve cooperation of mutual trust and benefit. Best Source will always stand ready to cooperate with you. Let's grow together!

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!

Write your message here and send it to us