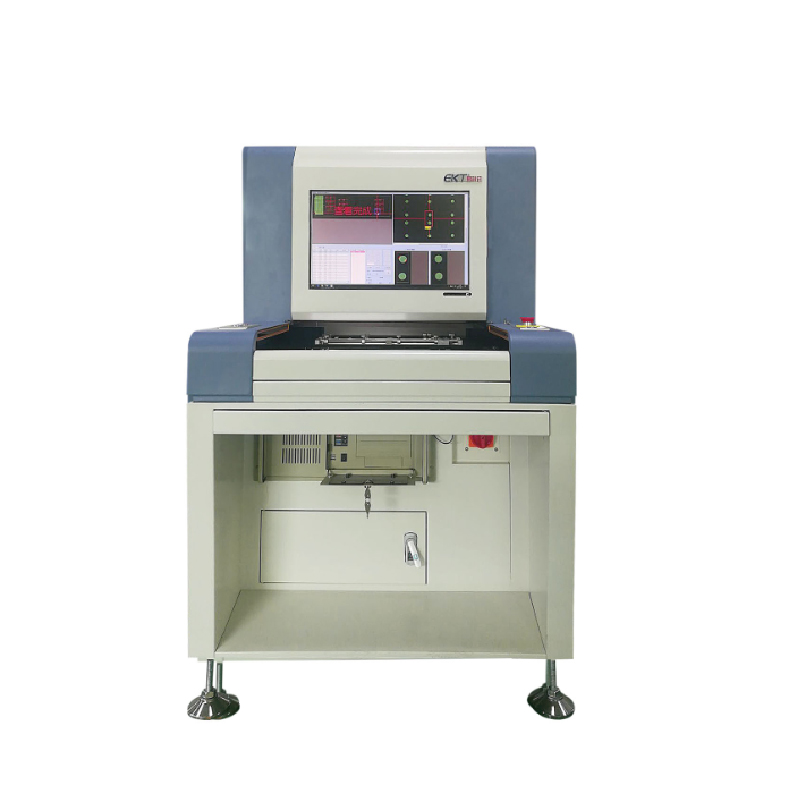

Advanced plus offline AOI EKT-VT-980

l Whole new appearance,more friendly design

l Customized high brightness wide view annular light source, light source, maximum FOV effective coverage area: 50*50mm, camera moving reduced and detect time shortened.

l Win10 64 bit OS,more stable

l CPU upgraded to i7 series,inspection speed faster

l Added vector analysis method, a series of improvements made to traditional algorithms such as color extraction.

Specifications: EKT-VT-980

| Inspection system | Application | After stencil printing, pre/post reflow oven, pre/post wave soldering, BGA tray,FPC etc. |

| Program mode | Manual programming, auto programming, CAD data importing | |

| Inspection Items | Stencil printing: Solder unavailability, insufficient or excessive solder, solder misalignment, bridging, stain, scratch etc. | |

| Component defect: missing or excessive component, misalignment, uneven, edging, opposite mounting, wrong or bad component etc. | ||

| Soldering defect: excessive or missing solder, empty soldering, bridging, solder ball, IC NG ,copper stain etc. | ||

| Calculation Method | Template matching, color calculation, vector analysis, color extraction, gray scale operation, characteristics analysis, OCV/OCR etc | |

| Inspection mode | PCB fully covered, with array and bad marking function | |

| SPC statistics function | Fully record the test data and make analysis, with high flexibility to check production and quality status | |

| Components angle | Angle 0~359°flexible,min angular distance 1° | |

| Min components | 01005 chip、0.3 pitch IC | |

| Optical system | Camera | 5 million pix full color high speed industrial digital camera , 20 million pix camera optional |

| Lens resolution | 10um/15um/18um/20um/25um, can be custom-made | |

| lighting source | Annular stereo multi-channel color light, RGB/RGBW/RGBR/RWBR optional, maximum FOV effective coverage area: 50*50mm | |

| Computer system | OS | Win 10, 64bit |

| Monitor | 22寸,16:10 | |

| CPU | Intel i7 series | |

| GPU | optional | |

| RAM | 16GB, may increase to 32GB | |

| HDD | 1TB , (SSD optional) | |

| Software | Language | Chinese, English optional |

| Access control | Admin/programmer/operator 3-level access control | |

| Mechanical system | Moving and inspection mode | Manual taking board in and out, Y servo motor driving PCB, X servo motor driving camera |

| Fixture | Auto fixture | |

| PCB dimension | 20*20mm(Min)~450*350mm(Max), can be customized | |

| PCB thickness | 0.3~5.0mm | |

| PCB weight | Max:3KG | |

| PCB edge | 3mm,can be customized | |

| PCB bending | <5mm or 3% of PCB Diagonal length | |

| PCB component height | Top:35mm,Bottom:75mm Adjustable, can be customized base on need | |

| XY driving system | AC servo motor, precise ball screw | |

| XY moving speed | Max:830mm/s | |

| XY positioning accuracy | ≦8um | |

| General parameters | Machine dimension | L1140 * W890 * H1500 mm |

| Power | AC220V,50/60Hz,1.5KW | |

| PCB height from ground | 820±20mm | |

| Machine weight | 450KG | |

| Safety standard | CE safety standard | |

| Environment temperature and humidity | 10~35℃,35~80% RH | |

| (non condensing) | ||

| Optional | configuration | Maintenance station, offline programming system, SPC servo, bar code system |

Write your message here and send it to us