18 Years Factory Pcb Board Inspection Equipment - Double rails online AOI EKT-VL-820 – Ektion

18 Years Factory Pcb Board Inspection Equipment - Double rails online AOI EKT-VL-820 – Ektion Detail:

Product Detail:

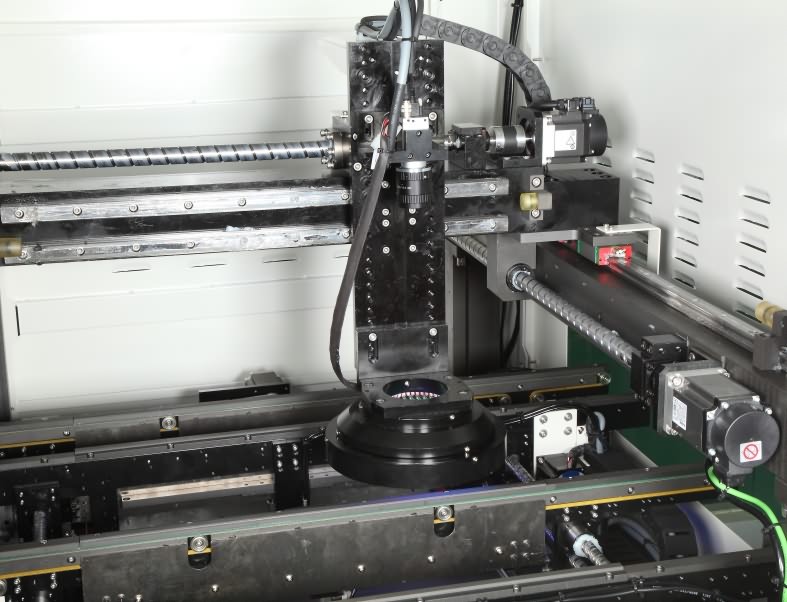

•One camera moving on XY direction, PCB transmitted by 2 conveyors.

•The 1st track fixed, the 2nd,3rd and 4th track adjustable.

•Applicable for various double conveyors production line.

•Fully compatible and retaining features of the series-8 single conveyor AOI products.

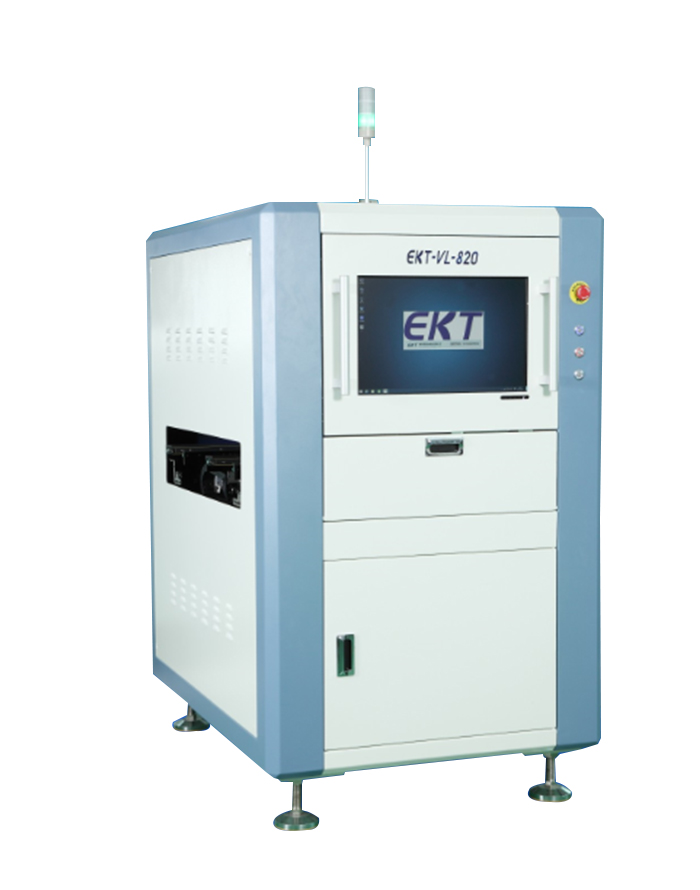

Double Conveyor Online AOI: EKT-VL-820

|

Inspection system |

Application |

After stencil printing, pre/post reflow oven, pre/post DIP wave soldering, FPC, etc |

|

Program mode |

Manual programming, auto programming, CAD data importing |

|

|

Inspection Items |

Stencil printing: Solder unavailability, insufficient or excessive solder, solder misalignment, bridging, stain, scratch etc. |

|

|

Component defect: missing or excessive component, misalignment, uneven, edging, opposite mounting, wrong or bad component etc. |

||

|

DIP :Missing parts, damage parts, offset, skew, inversion, etc |

||

|

Soldering defect: excessive or missing solder, empty soldering, bridging, solder ball, IC NG ,copper stain etc. |

||

|

Calculation Method |

Machine learning, color calculation, color extraction, gray scale operation, image contrast |

|

|

Inspection mode |

PCB fully covered, with array and bad marking function |

|

|

SPC statistics function |

Fully record the test data and make analysis, with high flexibility to check production and quality status. Image and test data saved simultaneously |

|

|

Components angle |

Angle 0~359°flexible,min angular distance 1° |

|

|

Min components |

01005 chip、0.3 pitch IC |

|

|

Optical system

|

Camera |

5 million pix full color high speed industrial digital camera, 20 million pix optional |

|

Lens resolution |

10um/15um/18um/20um/25um, can be custom-made |

|

|

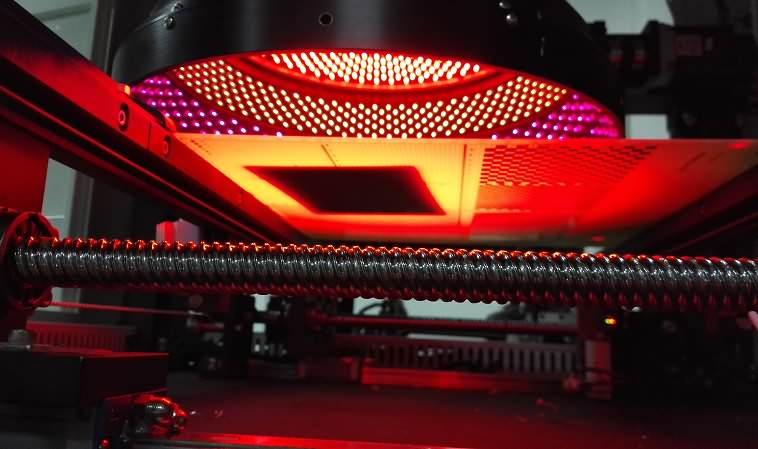

lighting source |

Annular stereo multi-channel color light, RGB/RGBW/RGBR/RWBR optional |

|

| Computer |

CPU |

Intel i7 3.40GHz |

|

GPU |

optional |

|

|

RAM |

16GB |

|

|

HDD |

1TB mechanical hard disk, SSD optional |

|

|

OS |

Win 7 64bit |

|

|

Monitor |

22 inch,16:10 (side sliding door) |

|

| Mechanical system |

Moving and inspection mode |

Stepping motor driving PCB auto-moving and width adjusting orbit; direction L-R or R-L optional; XY servo motor driving camera, double PCBA conveyor, width can be adjusted respectively. |

|

PCB size |

Both conveyor used:50*50mm(Min)~400*360mm(Max), single conveyor used: 50*50mm(Min)~460*650mm(Max), special size can be customized |

|

|

PCB thickness |

0.3~5.0mm |

|

|

PCB weight |

Max:3KG |

|

|

PCB edge |

3mm,special request can be custom made |

|

|

PCB bending |

Less than 5mm or 3% of PCB diagonal length |

|

|

PCB components height |

Top:35mm,Bottom:75mm. Can be adjustable and custom made |

|

|

XY driving system |

AC servo motor, precise ball screw |

|

|

XY moving speed |

Max:830mm/s |

|

|

XY accuracy deviation |

Less than 8um |

|

| General parameters |

Machine dimension |

L1440 * W1000 * H1620 mm, |

|

Power |

AC220V,50/60Hz,2KW |

|

|

PCB height from ground |

900±20mm |

|

|

Machine weight |

700KG |

|

|

Equipment communications |

Smema |

|

|

Air pressure |

0.4-0.8MPa,can adapt electronic control to avoid pressure limit |

|

|

Safety standard |

CE standard |

|

|

Environment temperature and humidity |

10~35℃,35~80% RH (non condensing)

|

|

|

|

Optional function |

Maintenance station system, offline programming system, SPC server system,bar code identification system |

Product detail pictures:

Related Product Guide:

We can constantly satisfy our respected customers with our good high quality, good price tag and good support due to we have been additional specialist and extra hard-working and do it in cost-effective way for 18 Years Factory Pcb Board Inspection Equipment - Double rails online AOI EKT-VL-820 – Ektion , The product will supply to all over the world, such as: Ghana , Surabaya , Sri Lanka , We have developed large markets in many countries, such as Europe and the United States, Eastern Europe and Eastern Asia. Meanwhile with the powerful predominance in persons with ability, strict production management and business concept.we constantly carry on self-innovation, technological innovation, managing innovation and business concept innovation. To follow the world markets fashion, new products are kept on researching and providing to guarantee our competitive advantage in styles, quality, price and service.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!